Articles

Message from Mike Farrington, M/SC Chairman: Efficiency = Competitive Edge

MCAA and our Supplier Partners know contractors aren’t just looking for solutions, you’re looking for Smart Solutions.

U.S. Engineering Fast-Tracks Project Using Trimble Technology

The new Mercy Hospital Joplin in Joplin, MO, is on schedule to open in 2015, thanks in part to efforts by U.S. Engineering. To meet…

FW Spencer Tackles Transportation Challenge with Anaco Husky Couplings

Prefabricating plumbing systems offsite can save time and money, but getting those systems to the jobsite poses its own challenges. For Levi’s Stadium in Santa…

MMC Contractors Credits Viega ProPress With “Tremendous” Time Savings on Solar Power Plant Job

The speed and ease of installation with Viega ProPress® fittings, as well as overall lower costs, were significant factors for MMC Contractors as they installed…

West Chester Mechanical Goes Digital with iBusiness Technology, Saves Time and Money

To streamline the large amount of paperwork generated by each project and jobsite and to make it easier for key project team members to access,…

Modern Piping Increases Productivity and Safety in the Field with Miller Electric’s Multiprocess Welding System

Modern Piping Inc. put the PipeWorx 350 FieldPro™ System from Miller Electric Mfg. Co. to work to save time and enhance safety for a job…

Palmer Christiansen Cuts Costs, Installation Time with Victaulic Grooved Products, Keeping Salt Lake City Courthouse on Schedule

With 24 months to install 130,800’ of pipe, Palmer Christiansen Company relied on Victaulic for high-quality systems that reduce labor costs and installation time. As…

Starco Maximizes Efficiency on School Project with GRINNELL Products, Services

To win the bid for a new Early Childhood Learning Center in Dayton, OH, Starco, Inc., proposed using GRINNELL products to speed installation time and…

John E. Green Company Earns High Marks for Campus A/C Retrofit Using Aquatherm’s Blue Pipe and Heat Fusion

To install a central air conditioning system in a high school campus’ main residence building during the short summer break, John E. Green Company called…

Easy Installation, Excellent Safety Profile Make TracPipe’s CounterStrike Ideal Choice for BMC

For the gas piping in the new Candlestick Heights apartment complex in San Francisco, CA, Broadway Mechanical-Contractors, Inc. (BMC), chose TracPipe CounterStrike® because it is…

Braconier Sees 50-Percent Labor Savings With Jay R. Smith Mfg. Co. Quarterback Water Closet Support

Minimizing installation time was an especially high priority for Braconier Mechanical & Plumbing Services’ work on a children’s hospital, so they used Jay R. Smith…

BMWC Safely Executes a Heavy Lift, Thanks to Lifting Gear Hire

For a challenging project with a short timeline, BMW Constructors, Inc. (BMWC), partnered with Lifting Gear Hire (LGH), who not only supplied the appropriately sized,…

ACCO Installs BITZER Compressors To Breathe New Life Into Medical Office Towers

By installing new BITZER compressors to replace aging, inefficient, and unreliable technology, ACCO Engineered Systems of Glendale, CA, helped Cedars Sinai Medical Towers in Los…

MMC Contractors Cuts Weeks Off of Hospital Project Using Autodesk’s Automated Point Layout

MMC Contractors credits Autodesk® Point Layout construction software with helping them shave weeks off the construction schedule for the Martin Army Community Hospital at Fort…

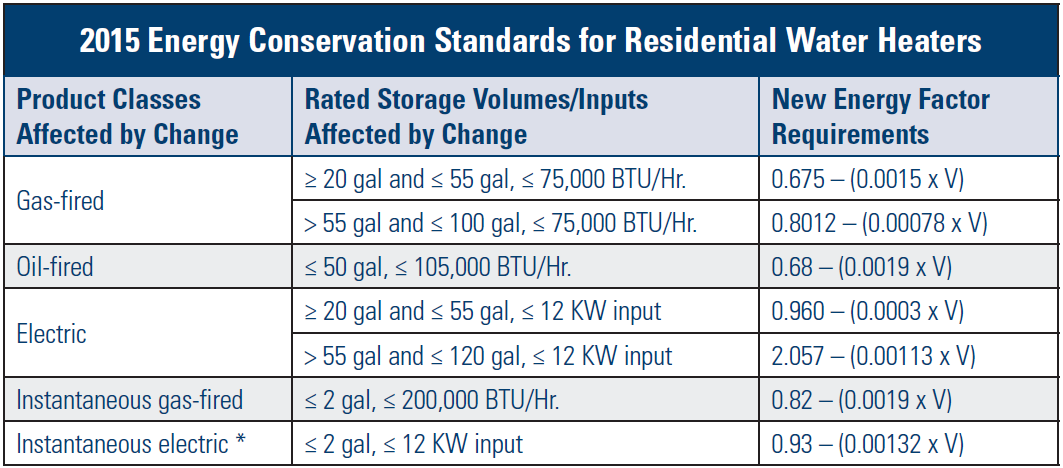

2015 Energy Efficiency Mandates Will Affect Water Heater Installations

The Department of Energy’s (DOE’s) new energy efficiency mandates, which take effect April 16, 2015, will require higher energy factor (EF) ratings on virtually all…

Atomatic Replaces Outdated Systems with WennSoft, Improves Efficiency, Boosts Productivity

By moving from an outdated accounting system to WennSoft Signature® and Microsoft® Dynamics® GP, Chicago-based HVAC firm Atomatic Mechanical Services dramatically streamlined its accounting processes,…

GPS Insight Offers Tips for GPS Buyers

A GPS tracking system can make your fleet more effective and efficient. GPS Insight suggests what to look for when buying a system.