Articles

Olson Plumbing and Heating Weathers Challenges of Pikes Peak Project with Viega ProPress

Prefabrication was just one of the ways that Olson Plumbing and Heating leveraged Viega ProPress to take on a mountain of a project: building a…

McKinstry Specifies Uponor Products to Save Energy and Installation Time

Following an energy audit, McKinstry specified Uponor’s flexible Ecoflex preinsulated piping to resolve a remote Minnesota school’s longtime heating problems and save the school thousands…

Message from Christopher Catania, M/SC Chair: Overcoming Challenges

MCAA and our Supplier Partners know contractors aren’t just looking for solutions, you’re looking for Smart Solutions.

Victaulic and Current Mechanical Achieve Perfect Harmony on Ambitious Expansion Project

For a demanding new warehouse project with a nine-month timeline, Current Mechanical counted on Victaulic’s experienced virtual design and construction (VDC) team, fabrication services, and…

CRW Mechanical Wins Bid with Labor-Saving Milwaukee Press Tool

CRW Mechanical won the bid for a parking garage’s gas piping project by switching to a Milwaukee® M18™ Force Logic™ Long Throw Press Tool rather…

Wayne Crouse, Inc. Cuts Installation Time with Marley Cooling Towers

Installing Marley® Cooling Towers from SPX Cooling Technologies, Inc., Wayne Crouse, Inc. shaved several days off of the schedule for a challenging project at a…

Daikin Magnitude Chiller & Optimized Controls Save Hospital More Than $70,000 per Year

When it came time for Luminis Health Doctors Community Medical Center (LHDCMC) of Lanham, MD, to update its aging HVAC infrastructure, it quickly awarded the…

Sloan’s Keys to a Successful Water Savings Project

You have probably heard about “the five Ps:” Proper planning prevents poor performance. This concept is particularly important when embarking on a commercial retrofit project…

FARO’s Laser-Based Reality Capture Tools Cut Limbach’s Labor Costs

FARO Technologies Inc.’s FARO® Focus S 350 Laser Scanners “are really allowing us to send one guy in to a project and capture in a…

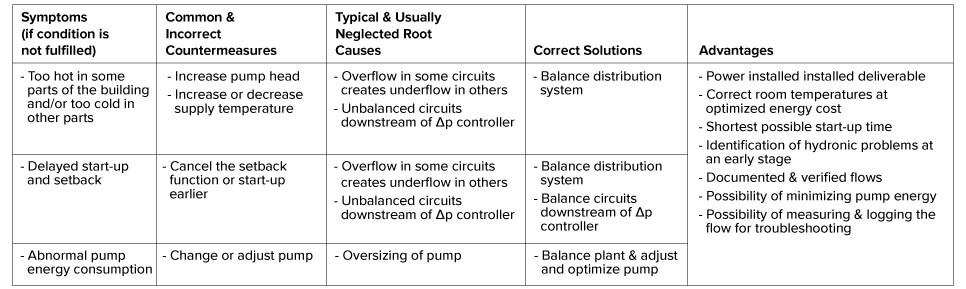

IMI Hydronic Engineering Describes Keys to Perfect Hydronic Climate Control

The ultimate goal of every heating and cooling installation is to provide the desired indoor climate at the lowest possible energy cost. Today’s advanced control…

Procore Software Boosts Monterey Mechanical’s Productivity, Saving One Day Per Employee Per Week

By installing Procore software, Monterey Mechanical Co. was finally able to offer mobile information access to everyone on its team. The efficiencies gained work out…

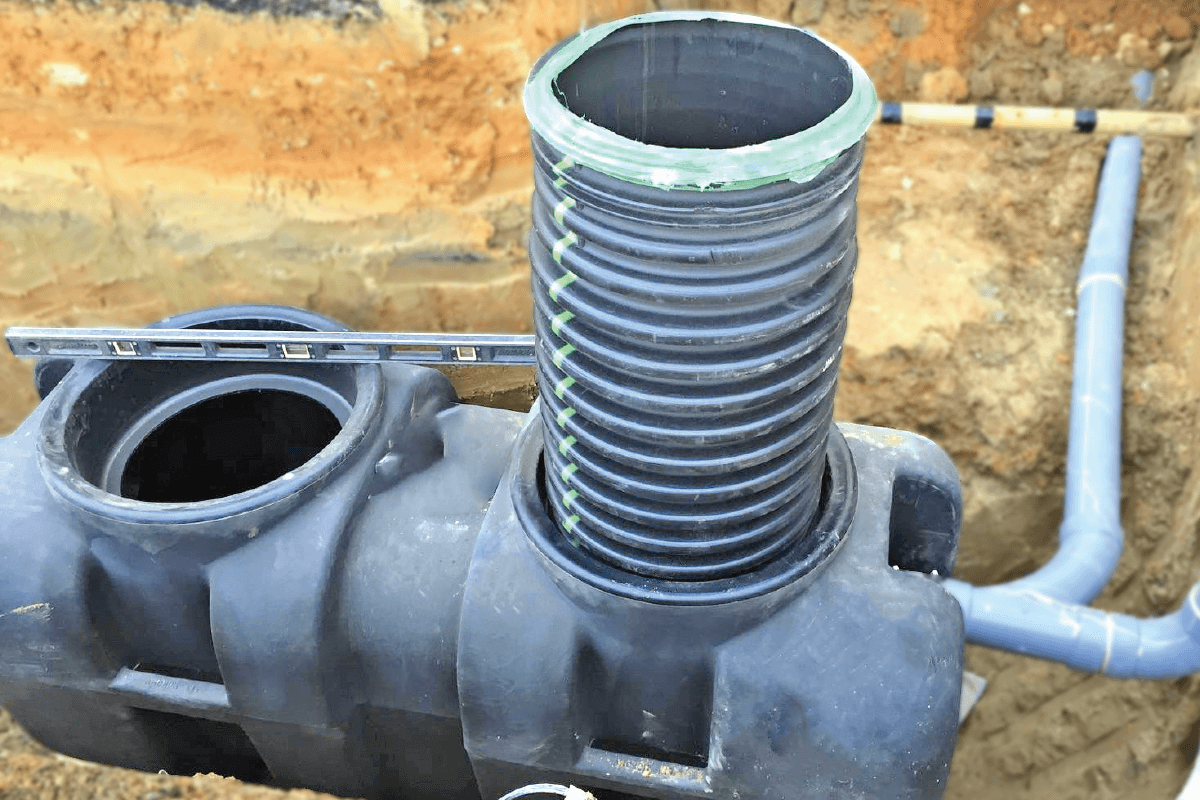

Bayer’s Plumbing Finds Perfect Fit with Easy-to-Install MIFAB HDPE Interceptors

When Bayer’s Plumbing of Newburgh, IN, needed a modern grease interceptor solution for a local deli, they turned to MIFAB for a product that cost…

Using MSUITE and Prefabrication, Limbach Completes Hospital Project Two Months Ahead of Schedule

With MSUITE’s FabPro software, Limbach successfully streamlined operations in a pop-up fabrication shop with multiple trades working side-by-side, minimizing assembly and installation time. The combination…

Atomatic Handles Increased Workload With XOi App

Atomatic Mechanical Services Inc. credits XOi with helping them manage their workload. “Before using XOi, we were on the brink of having to hire more…

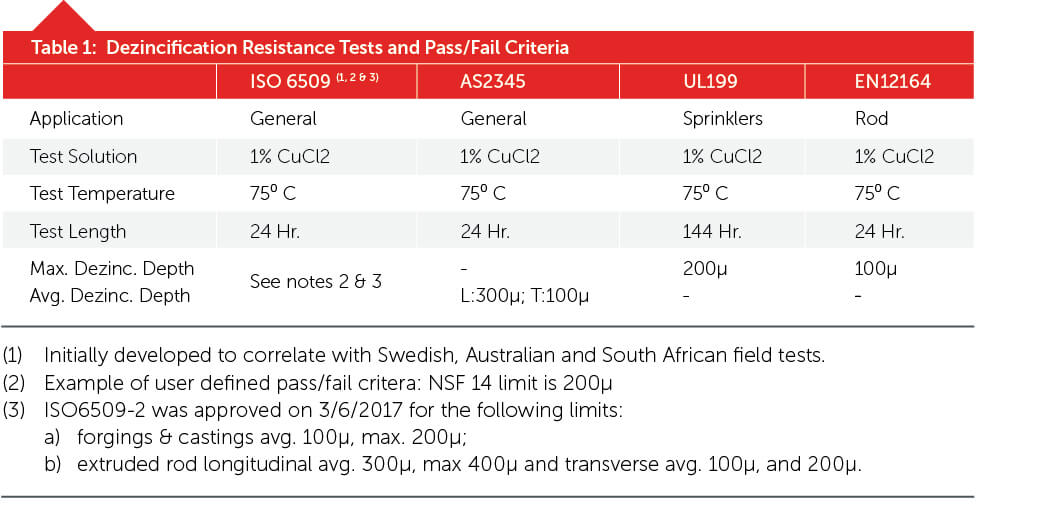

Dezincification: Breaking the 15-Percent Zinc Wall

Some technical papers and websites on brass corrosion repeat the same caution that dezincification will occur in alloys containing more than 15-percent zinc. A few…

Marking Services Inc. Makes Hospital’s Documents Easily Accessible, Saving Money and Ensuring Regulatory Compliance

AIM Mobile Technology and Field Implementation Services from Marking Services Inc. (MSI) allow Boston Children’s Hospital (BCH) to keep track of documents for thousands of…

Lochinvar and EMCOR Services-Betlem Partner to Provide Energy Efficiency

Lochinvar boilers installed more than 25 years ago on Finger Lakes Community College’s (FLCC’s) main campus delivered state-of-the-art high efficiency in their day, but the…

Piping Systems Slashes Cutting Time and Increases Capacity With Watts-Mueller Machines

Piping Systems Inc. invested in a Watts-Mueller cutting system when it became clear that its current tools were too slow for jobs involving large-diameter pipe.…