Articles

Maxair Mechanical and Victaulic Streamline Complex Med School Project From Design to Startup

For a new, state-of-the-art medical school campus, Maxair Mechanical saved valuable time by installing “miles of piping” using Victaulic products rather than welding and relying…

JPG Increases Efficiency, Builds Business With Zurn SmartPro Monitoring

JPG Plumbing & Mechanical Services’ adoption of new oil and grease interceptor monitoring technology from Zurn has significantly reduced pumping overspend and minimized the risk…

Message from Christopher Catania, M/SC Chair: Staying Ahead of the Game

Whether it’s labor shortages, supply chain challenges, tight deadlines, or other hurdles, MCAA members and manufacturer/supplier partners are finding smart solutions to stay ahead of…

A&R Mechanical Overcomes Supply Chain Challenges Building Illinois Softball Center Thanks to NIBCO

Breaking ground on the Rex and Alice A. Martin Softball Training Center at the University of Illinois in April 2021, A&R Mechanical Contractors, Inc., faced…

Stand Out by Incorporating Inclusive Restroom Design: Tips From Sloan

Barrier-free, accessible, and inclusive design is an important trend in building. Planning for a commercial restroom with all users in mind, regardless of ability, gender,…

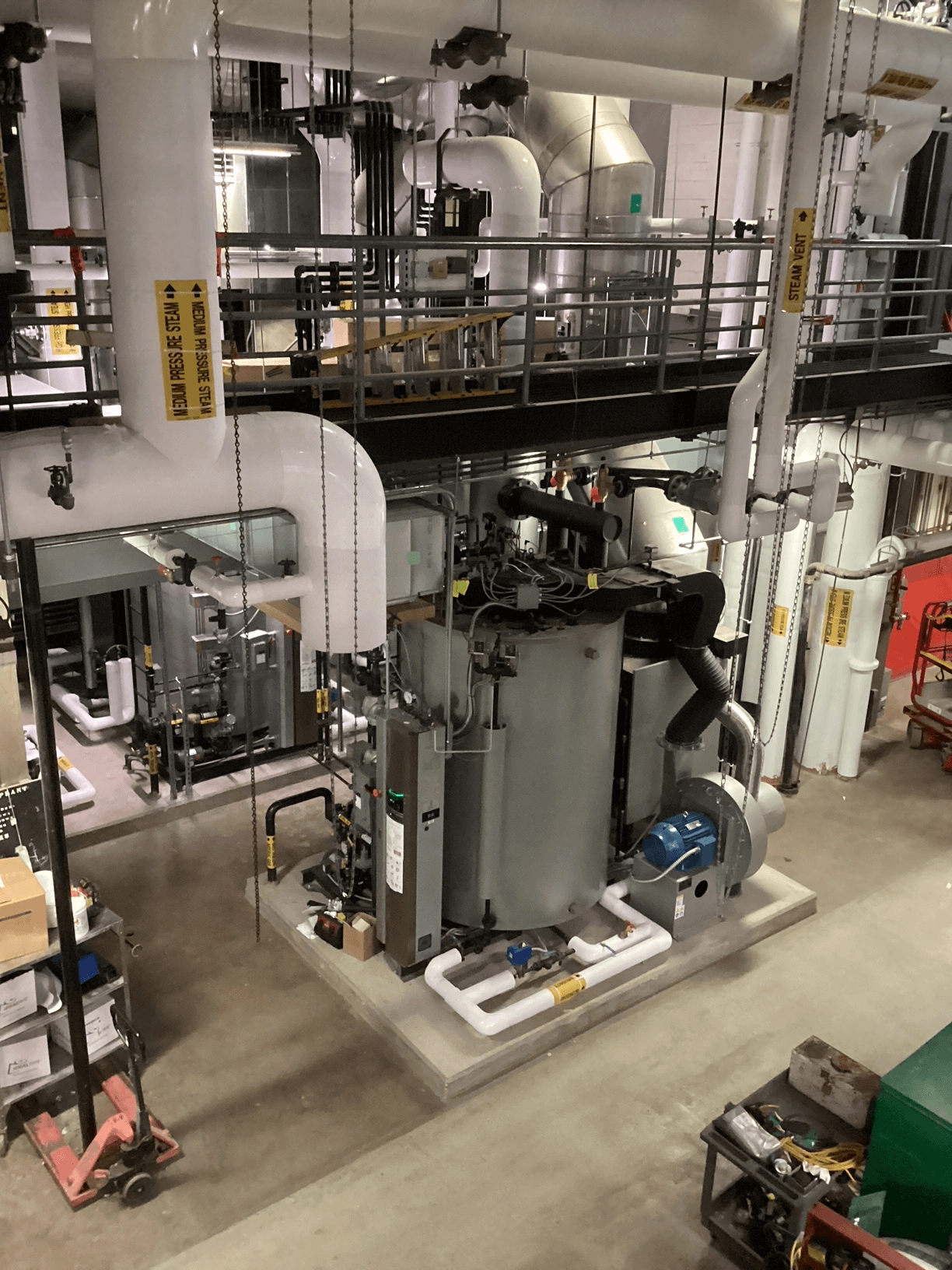

Danforth Turns to Mueller Industries’ Streamline Press Fittings to Meet Hospital Project Demands

A new, state-of-the-art hospital in New York required that John W. Danforth Company use solder connections for mechanical piping and press fittings for the plumbing,…

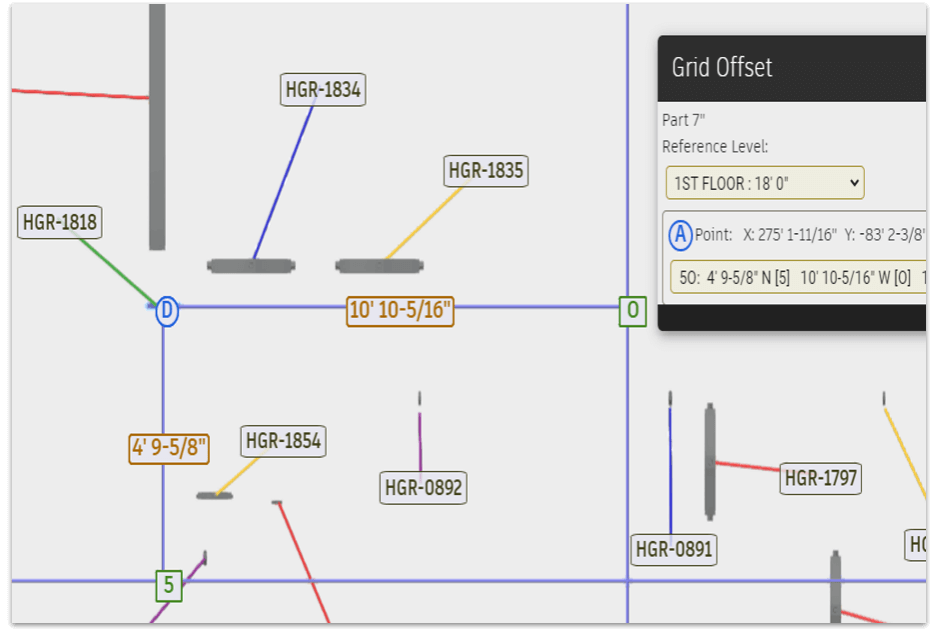

Silicon Valley Mechanical Improves Productivity, Efficiency With PypeServer Enterprise Software

Silicon Valley Mechanical, a full-service mechanical contractor in San Jose, CA, rapidly improved productivity and increased efficiency by putting PypeServer software into place. Here, Jamie…

IMI TA’s Support Center Cuts Energy Costs at Oklahoma Public Safety Facility

Close collaboration between IMI TA, a branch of IMI Hydronic Engineering, and building designers led to a 23-percent savings in annual energy consumption (equivalent to…

Josam Company’s Lightweight Drain System Makes Installation a Snap for Egan Company

Egan Company selected Josam Company’s drain system to ensure that LeafLine Labs, the premium medical cannabis cultivator in Minnesota, had the right drainage systems to…

Simplifying the Way We Capture and Transfer Knowledge

With more than 70 million baby boomers set to retire by 2030—more than 10,000 each day—organizations need to rethink the way they capture and transfer…

Bluegrass Hydronics and Pump Turns Emergency Replacement Into No-Cost Upgrade With Delta Cooling Towers

By installing antimicrobial cooling towers from Delta Cooling, Bluegrass Hydronics and Pump helped a rural Kentucky school district qualify for a federal grant to replace…

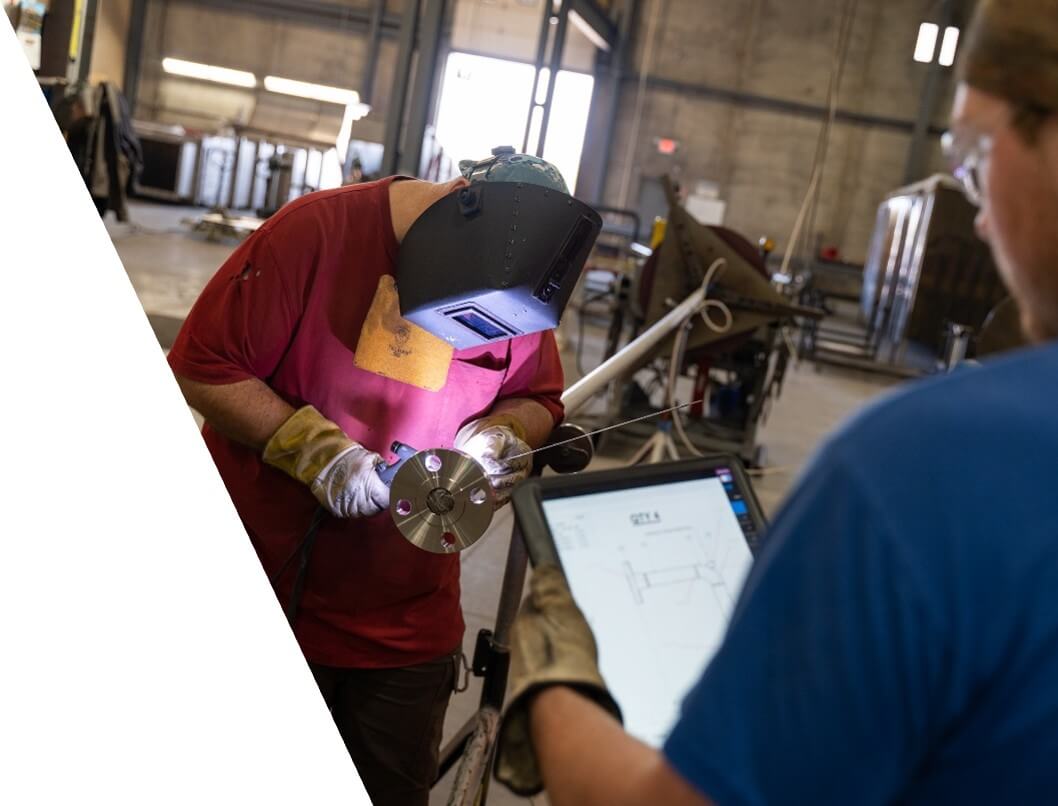

Harder Mechanical Tackles Welder Shortage, Amps Up Productivity With Novarc’s Spool Welding Robot

By implementing Novarc’s Spool Welding Robot (SWR), Harder Mechanical Contractors has minimized their need for highly skilled welders and increased productivity from an average of…

Ridge Tool Company Offers Tips for Selecting Ergonomic Tools to Minimize Strain, Increase Productivity

Not long ago, the impact of a tool on its user was not given much thought when it came to tool design. Today, thanks to…

CNA Risk Control e-Talks Offer Insights Into Business Resilience

You cannot eliminate the possibility of business disruptions—but you can prepare for them. Whether the cause is a storm, a cyberattack, or another unexpected event,…

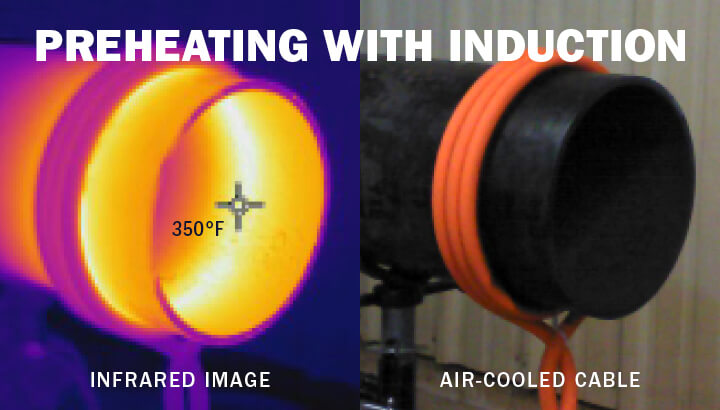

Miller Electric Illustrates Benefits of Induction for Welding Preheating

Welding preheating is used to ensure weld quality and reduce the chance of cracking and other defects that can result in costly rework. Preheating is…

Pipe Fabrication Institute Standards Help Contractors Meet Demanding Criteria

Complex and sensitive facilities—such as nuclear and fossil fuel plants, refineries, steel and paper mills, chemical processing plants, and semiconductor and pharmaceutical manufacturing plants—require sophisticated…

Raken Outlines Five Ways to Manage Generational Gaps on the Jobsite

From apprentices to expert craftsmen, the construction industry employs a workforce that spans multiple generations. While an age-diverse workforce brings well-rounded skills and experiences to…

Postler & Jaeckle Boosts Productivity Using GTP’s STRATUS Manufacturing and Installation Labels

With a goal of eliminating paper in the shop, increasing efficiency in cutting, and using barcode labels to improve shop workflows, Postler & Jaeckle started…

FARO Offers Five Tips for Maximizing Profitability With 3D Reality Capture

When processes are not aligned at every stage of a construction project, costly delays and unnecessary expenses are inevitable—and in the worst-case scenario can even…

Graco Mechanical Upgrades Houston Highrise in One Weekend with Marley Cooling Towers

For Graco Mechanical of Houston, TX, Marley NC® Cooling Towers from SPX Cooling Tech, LLC proved to be the ideal solution for replacing a highrise…

Engineered Water Heater Solutions Versus Field-Devised Methods: Advice From Reliance Worldwide Corporation

Confidence in your installation and its reliability are important to any contractor, but labor shortages and economic constraints can often make you feel like you…

F+F Mechanical Slashes Pipe Cutting Time and Labor Costs With Watts-Mueller Machine

Recognizing that pipe fabrication was slowing down its prefabrication process, F+F Mechanical Company invested in a Watts-Mueller pipe cutter that dramatically improved speed and quality…

McKinstry Relies on MSUITE to Gain Productivity Insights Across the Enterprise

McKinstry set out to gather more insight into fabrication shop productivity and enhance the connection between its Virtual Design and Construction (VDC) and Fabrication teams.…

Therma Bridges Creativity and Collaboration with Procore’s Construction Management Platform

Therma’s steady growth and sterling reputation over the decades has been driven in part by its highly motivated and skilled innovators, each with their own…

ServiceTrade Helps B&W Mechanical Put Customers First, Building Long-Term Loyalty

B&W Mechanical, one of the largest mechanical contractors in the Southeast, chose ServiceTrade software to help them make the move from paper to digital, shortening…

A. O. Smith Water Heaters Provide Reliable Hot Water at Any Hour for Hotel Guests

A hospitality industry veteran opted for A.O. Smith for a dependable water heating solution for a new four-story Hampton Inn in Ashland City, TN. “Hampton…