Articles

Message from Frank Schaetzke, MS/C Chairman: Prefab, Products, and Productivity

MCAA and our Supplier Partners know contractors aren’t just looking for solutions, you’re looking for Smart Solutions.

ACCO Pairs BIM and Daikin McQuay Chillers for North America’s Greenest Urban Office Building

Commitment to energy-efficient products such as Daikin McQuay’s Magnitude® chillers and reliance on building information modeling (BIM) to manage a complex project helped ACCO Engineered…

U.S. Engineering Company Improves Productivity, Cuts Costs Using Prefabrication with Victaulic Grooved Technologies

For U.S. Engineering Company, finding creative ways to keep the University of Colorado Hospital’s (UCH’s) new expansion on track helped them increase productivity while delivering…

Hart Engineering Minimizes Facility’s Downtime Thanks to Speed of Viega ProPress for Stainless

Faced with the challenge of replacing all of a biotechnology company’s existing piping with stainless steel in just 14 weeks, Hart Engineering found that Viega…

CFI Mechanical Completes Healthcare Facility Ahead of Schedule Using Technical Sales International BIM Software, Tools, and Prefabrication

When CFI Mechanical in Houston, TX, took on an $8.5-million mechanical job with an aggressive schedule requiring massive coordination before the structure was built, they…

Smith & Oby Combines Prefabrication and ERICO’s New CADDY ROD LOCK System to Cut Installation Time

In early 2011, Smith & Oby Company began work on a new office building in Cleveland, OH, that included 250 active chilled beams, which required…

Think You Don’t Need a DOT Number? Think Again!

There has been much confusion about who is required to have a U.S. Department of Transportation (USDOT) number. Many contractors feel it’s only needed for…

Jay R. Smith Mfg. Co.’s Enviro-Flo Solves Arena’s Unique Drainage Problem

All stadiums and arenas tend to get dirty, but an arena floor covered in dirt poses a unique problem. Keeping such an arena clean is…

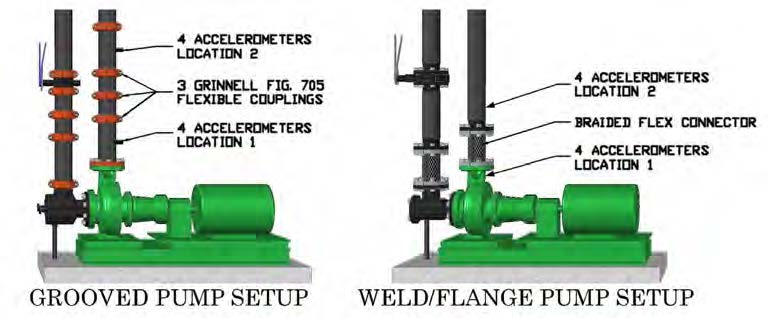

GRINNELL Grooved Couplings Provide Tight Seals Plus Noise Reduction

To address the challenge of vibration noise from pipes, GRINNELL Grooved Flexible Couplings reduce vibrations, minimizing the amount of noise distributed through a pipe system,…

Tweet/Garot Teams Up with Bidtracer for Renovation of Green Bay Packers’ Lambeau Field

To win the contract to renovate the Green Bay Packers’ Lambeau Field, Tweet/Garot of Wisconsin put Bidtracer’s invitation management software to work to solicit bids…

ACCO Builds on WennSoft Technologies to Increase Efficiency and Return on Investment

In 2012, ACCO Engineered Systems of Glendale, CA, trained more than 200 service technicians to use its new MobileTech system, tailored for ACCO by WennSoft,…

Weld Positioners Improve Productivity and Quality

While most weld positioners will improve the productivity of a pipe welder, a positioner designed specifically for the pipe welding industry to reduce welder fatigue…

Pyke Mechanical Chooses High-Efficiency BITZER Screw for Compressor Retrofit

When the Miami International University of Arts and Design needed to upgrade its chiller, Pyke Mechanical was able to install a new, high-efficiency BITZER Screw…

Popular Rental Equipment Can Meet Contractors’ Immediate Needs

The need for specialized equipment may arise so infrequently that a company cannot afford to purchase it. Moreover, storing, maintaining, and, in some cases, certifying…