Articles

Message from Jim Allen, M/SC Chairman: Innovation on Your Side

MCAA and our Supplier Partners know contractors aren’t just looking for solutions, you’re looking for Smart Solutions.

With Jay R. Smith Customized Solutions, Naval Hospital Completed Early, Under Budget

To overcome multiple and unusual challenges—including concerns about terrorism—Pan-Pacific Mechanical, in partnership with Murray Co., and A.O. Reed, collectively known as RPM, called on Jay…

CFI Mechanical Overcomes Skilled Labor Shortages with Victaulic Products and Services

Building information modeling (BIM) and 3D modeling offered by Victaulic’s Construction Piping Services (CPS) division helped CFI Mechanical manage the lack of detailers available in…

Arista Relies on Mitsubishi Electric Systems to Keep Restaurant Customers Comfortable in Any Weather

Thanks to years of experience serving the New York City area, Arista Air Conditioning Corporation knew that a Variable Refrigerant Flow (VRF) zoning system from…

TG Gallagher Prescribes BAC Cooling Towers for Easy Installation, Efficiency

With only two consecutive weekends scheduled to replace Cambridge Hospital’s aging cooling towers, TG Gallagher selected Baltimore Aircoil Company (BAC) towers designed to make installation…

Johnson Controls Offers High-Tech Connections to Monitor Equipment

Johnson Controls, Inc. combined its YORK® chillers and Metasys® software technology to help contractors monitor the health of installed chillers during the warranty period so…

Autodesk’s Smart Hardhat Software Alerts Workers to Onsite Dangers

Autodesk’s mobile software prototype communicates with dust and noise pollution sensors attached to a hardhat and tracks when levels become dangerous, offering the potential to…

Donald C. Rodner, Inc. Cuts Labor Costs, Billing Time by Going Mobile

By adopting MobiliForms software from iBusiness Technologies, Donald C. Rodner, Inc. sped up their invoicing time and cut down on labor costs while still using…

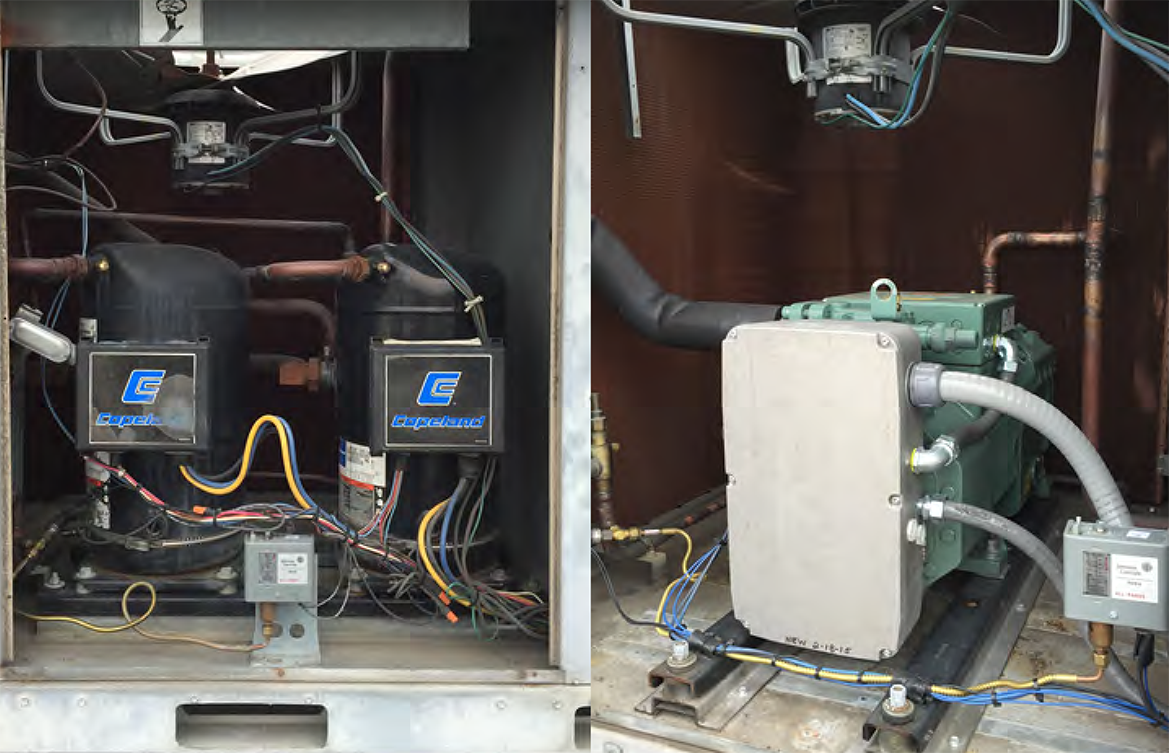

ACCO Gets Creative, Uses Single BITZER Compressor to Replace Tandem Units

When a major animation studio needed to replace a compressor and upgrade its systems, ACCO Engineered Systems took an unusual approach, replacing a tandem scroll…

Conti Corporation Cuts Installation Time with Erickson Incorporated Aerial Lift and Placement

Innovative aerial service provider Erickson Incorporated successfully conducted 13 chiller equipment lifts to the top of the JPM Chase building in Belleville, MI, in just…

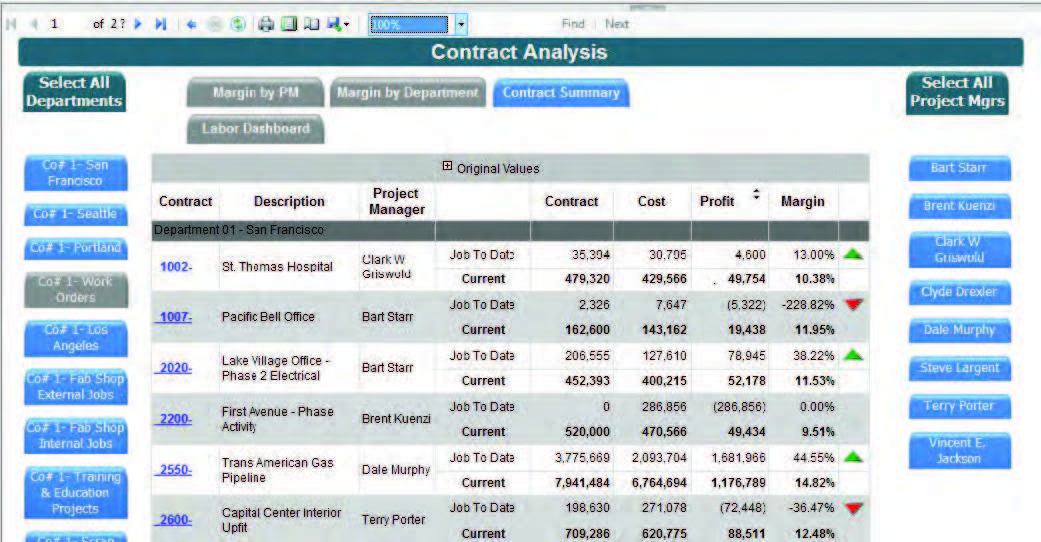

Bassett Mechanical Streamlines Payment, Reporting Processes with Viewpoint Software

By replacing their outdated accounting and management software with easy-to-use, flexible Vista™ by Viewpoint, Bassett Mechanical has improved efficiency and streamlined billing processes. “It’s important…

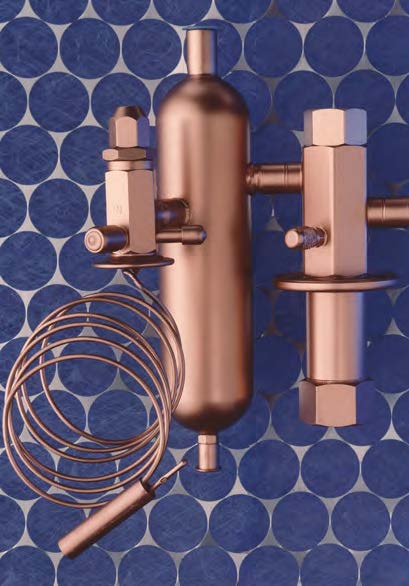

The Warko Group Strikes Perfect Humidity Balance with Rawal Devices

Pharmaceutical specialty and medical device manufacturer Angiotech had tried almost everything to keep humidity levels in its cleanrooms just right, but only the APR Control…

Tri Tool Customized Machinery Allows Unprecedented Relocation of Live Communication Lines Without Service Interruption

When a California transit project called for excavating and relocating buried telecommunication cables in Silicon Valley—while the cables remained live—Tri Tool Inc. created novel machinery…

MacDonald Miller Turns to HOLDRITE to Stop Leaks, Provide Watertight Solutions

Midway through construction in downtown Seattle, MacDonald Miller was relieved to find that the HOLDRITE® HydroFlame™ sleeving system not only fixed the leaks that had…