Want to Grow Your Business? Register for the PCA Plumbing Service Conference

While the construction industry has bounced back from the lows of 2020, the pandemic has helped teach contractors a valuable lesson – growing your business can help you ride out the low times. Plumbing service presents a perfect opportunity for plumbing, mechanical and mechanical service members to grow their business into new sectors. The ideal time to start the process is now when backlogs are full. The PCA Plumbing Service Conference presents a great opportunity to learn how to add service to your business.

As Neptune Plumbing CEO and PCA Chair Scott Wallenstein puts it, “We started getting into plumbing service a couple of years before The Great Recession. When times were low in 2007 and 2008, plumbing service was a great way to compensate for the slowdown in our construction department. Now we see it as a cornerstone of our business because of the higher margins, cash flow and regular business through maintenance agreements.”

The PCA’s new Plumbing Service Conference is a great way to learn how contractors have added plumbing service operations. While attending the conference, you can see it in action. Join a tour of Neptune Plumbing’s Cleveland facility to see how they perform their plumbing service operations. They will demonstrate how they handle inventory, dispatch, stock a plumbing service truck and perform comprehensive plumbing service operations.

The conference will be held September 20-21 in Cleveland, Ohio and limited to only 50 participants. The conference is filling up fast, so register now! To learn more, or to reserve your spot, visit our event page.

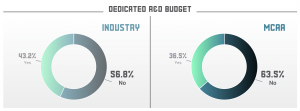

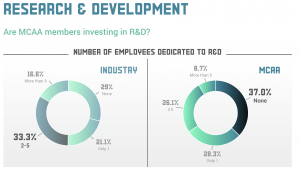

Most respondents that identified as MCAA members reported that they had one or two people dedicated to R&D, while 37% do not have employees dedicated to R&D. During a presentation on the topic at MCAA19, MCAA’s Director, Construction Technology Sean McGuire explained, “While we are seeing more members take technology seriously, smaller companies are going to always be more limited on budget and manpower that they can dedicate towards research and implementation. Larger GCs and CMs can absorb these costs a little easier simply as a function of their size.”

Most respondents that identified as MCAA members reported that they had one or two people dedicated to R&D, while 37% do not have employees dedicated to R&D. During a presentation on the topic at MCAA19, MCAA’s Director, Construction Technology Sean McGuire explained, “While we are seeing more members take technology seriously, smaller companies are going to always be more limited on budget and manpower that they can dedicate towards research and implementation. Larger GCs and CMs can absorb these costs a little easier simply as a function of their size.”

These missing tools and artful uses are often easy to see on a job site or in the Fab shop. That’s why I think Con Techs should spend a considerable amount of time observing or possibly working with the craftsmen in the field looking for missing tools, materials, methods and potential artful use. Every time I step on a job site I look at what craftsmen do with their tools with an eye to unconventional uses. Some of the best ideas have grown out of watching people use their tools in some absurd way. That can communicate louder than words what is really needed.

These missing tools and artful uses are often easy to see on a job site or in the Fab shop. That’s why I think Con Techs should spend a considerable amount of time observing or possibly working with the craftsmen in the field looking for missing tools, materials, methods and potential artful use. Every time I step on a job site I look at what craftsmen do with their tools with an eye to unconventional uses. Some of the best ideas have grown out of watching people use their tools in some absurd way. That can communicate louder than words what is really needed.