Metropolitan Mechanical Contractors, Inc. (MMC) put Novarc Technologies Inc.’s Spool Welding Robot™ (SWR) to work and dramatically increased their welding capacity, achieving consistent, high-quality welds every single time. Corey Hagerty, pipefitting shop foreman at MMC, described the impact: “Before implementing the SWR, we typically had three to four guys welding (depending on the project) and we averaged from 60 to 80 factored diameter inches (FDI) a day. Currently, we’re doing 200 to 250 FDI a day on the SWR; we even achieved 290” in one day.”

MMC has an impressive portfolio of completed projects including the Mall of America, Target Center, Target Field, and the Xcel Energy Center. “The SWR has helped with our capacity on the larger projects, and that’s definitely where we have shined,” said Hagerty.

Aiming for Quality and Consistency

When evaluating pipe welding automation systems for their fabrication shop, MMC was looking for a solution that would help them achieve consistent, high-quality welds. “The projects that we work on vary a lot,” said Hagerty. “Specific jobs typically require a percentage for X-ray and ultrasound testing. Sometimes we run into jobs where it is 100% X-ray and sometimes 10%. What was important to us was to improve the quality and consistency of our welds.”

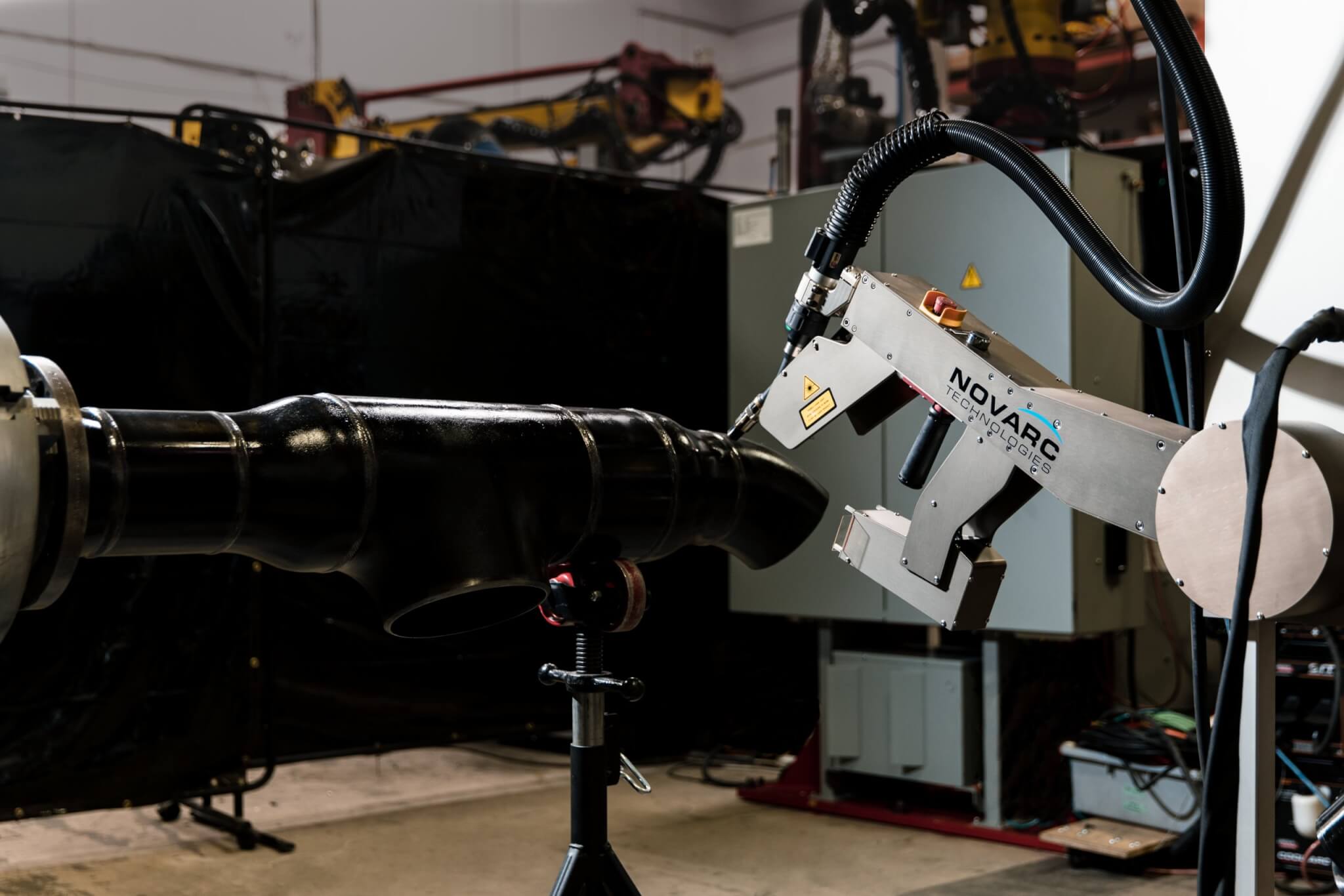

Novarc’s SWR is a welding cobot designed specifically for pipe, small pressure vessels, and other types of roll welding. Since implementing the SWR, MMC has increased their pipe welding capacity dramatically, with no failures or repairs needed to date. In North America, repair rates at pipe fabrication shops are typically around 3 to 5 percent. A shop producing 6,000 welds per year with a 5-percent repair rate is likely spending around $300,000 each year on repairs. At MMC, Hagerty noted, “The cost of repairs is typically between $800 and $1,000 per test, and with Novarc we’ve achieved a 0-percent failure rate.”

Tackling the Welder Shortage

The SWR has reduced MMC’s dependence on highly skilled welders, of whom there is a global shortage. With the SWR, MMC has been able to leverage the skills of its current workforce. Hagerty explained, “We actually have an individual that was a pretty skilled welder in the field of stick welding, and he didn’t have a significant amount of experience in wire, but he just obtained certification with wire, and we’ve been able to put him on the SWR. It’s been pretty seamless to be able to put a junior-level welder on the SWR and achieve high-quality welds.”

Learn more about MMC’s experience with Novarc during this online chat with Corey Hagerty: https://www.novarctech.com/videos/

In addition, Novarc has helped MMC get the most out of their SWR. “Novarc’s support team has been very helpful, and they ensured that we were up and running all the time,” said Hagerty. “I really like the platform that the team has in the background; basically, if there is an important issue, they see it and they take care of it right away. They have a gauge on who takes care of it, how, and why.”

Hagerty also praised Novarc’s training opportunities. “The Novarc Academy was also a great help. I had walked through the training sessions myself, and I think that it took out a lot of the unknown and the pessimistic views that a lot of welders can have towards it. The fact that you can override it, interact with it, and make adjustments on the fly is a huge benefit. I fully believe that’s the benefit to Novarc over the other semi-automatic processes,” Hagerty concluded.

For more information, visit www.novarctech.com.