Thanks to photos and videos captured onsite by OpenSpace technology, U.S. Engineering fixed an error during construction that would have required expensive rework if it had not been caught early. With OpenSpace, U.S. Engineering managers are keeping tabs on projects remotely, saving hours of travel time and costs.

True As-Built View Improves Quality

As quality control manager for U.S. Engineering, Chad Lucks routinely travels across the Rocky Mountain region to oversee projects. He wanted a better way to document the many jobsites he was tasked with monitoring than notes jotted down by colleagues and cell phone pictures, which could be unreliable and inconsistent. He also hoped to reduce his commuting time with technology that would help him stay on top of more than a dozen projects at any given time, even remotely.

“Through the detailed documentation OpenSpace provides, we have a true as-built.”

—Chad Lucks, Quality Control Manager, U.S. Engineering

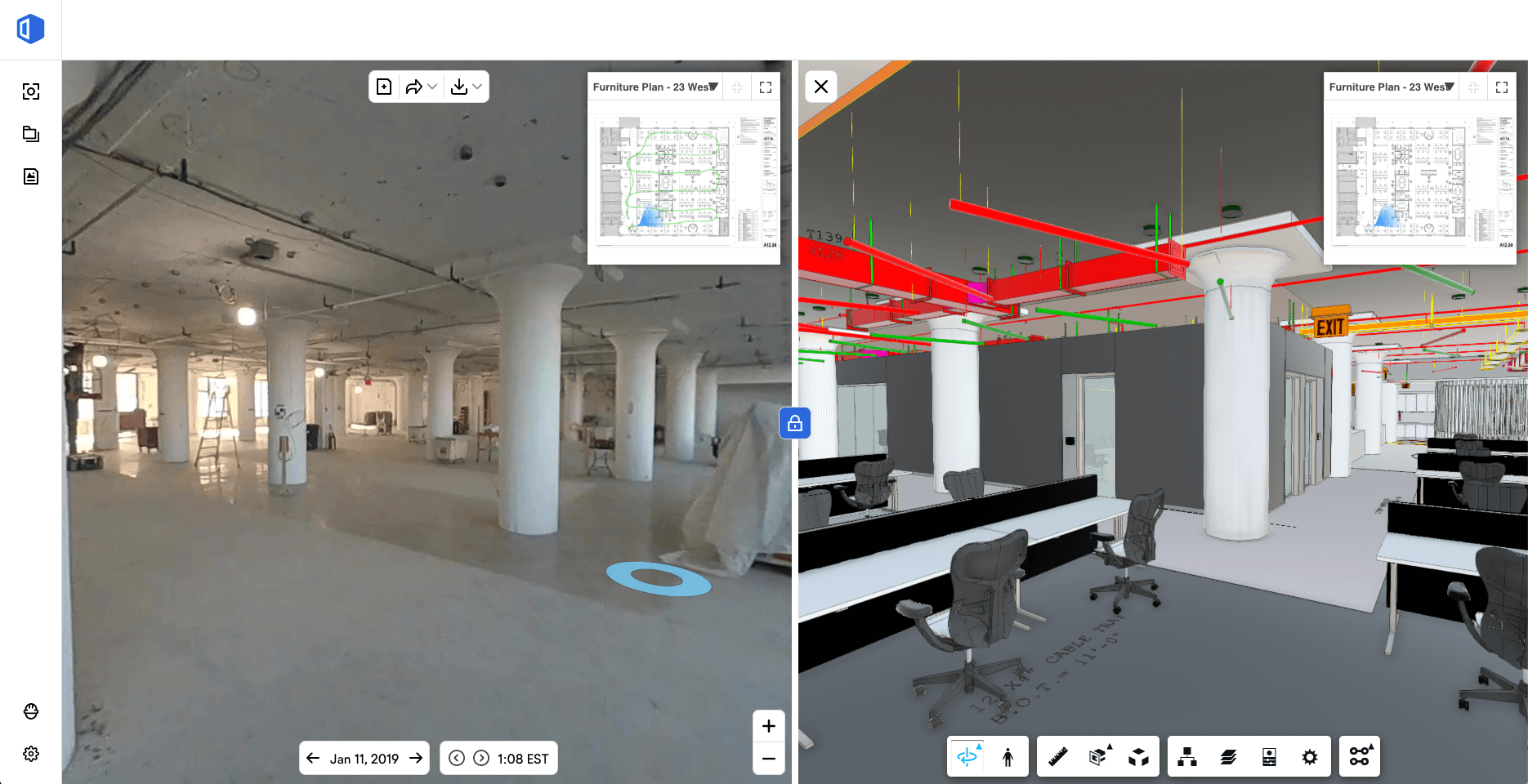

Lucks started using OpenSpace to capture his projects, including hospitals in North Dakota and Arizona, a Target in Boulder, CO, and a public school system in Denver, CO, with the main objective of reducing risk. He soon began relying on the BIM Compare feature (which shows a side-by-side view of actual site conditions with the model) for day-to-day work. “I switched to OpenSpace because I can be anywhere and reference the drawings and model we’re using in Arizona, for example, alongside what’s really happening onsite,” Lucks explained.

OpenSpace has proved easy to learn, and project engineers can capture sites by simply strapping a 360° camera to their hard hats and walking. OpenSpace automatically generates a Google Street View-style video of the project. Lucks typically plays the video at half-speed to look carefully for discrepancies and issues from his office.

Having a single source of truth helps everyone get on the same page. For example, Lucks recently noticed in BIM Compare that a section of piping and valves present in the model was missing in a ceiling. He created a Field Note in OpenSpace, assigned it to the virtual design construction technician, and linked it to Procore. From there, the team confirmed there was an error in the as-builts, which was corrected. Because Lucks caught the discrepancy before the ceiling was closed up, U.S. Engineering avoided potential rework costs if the mistake had only been noticed months later.

“Paper as-builts are old-school and going away,” said Lucks. “Through the detailed documentation OpenSpace provides, we have a true as-built, which is better for maintenance and the owner at the end.”

“I switched to OpenSpace because I can be anywhere and reference the drawings and model we’re using in Arizona, for example, alongside what’s really happening onsite.”

—Chad Lucks, Quality Control Manager, U.S. Engineering

Streamlining Processes

U.S. Engineering is also using OpenSpace Track to automatically generate completion percentages for sheet metal installation, which facilitates monthly pay applications and saves time. Lucks also thinks it benefits superintendents by helping them understand whether teams are falling behind on a project. U.S. Engineering Project Manager Aaron Denning is using OpenSpace Track to track sheet metal installation and forecast how much sheet metal should be brought to the project, so materials are not sitting onsite for weeks before they are needed.

Lucks is using OpenSpace’s 3D Scan feature to scan electrical and ductwork near ceilings to measure them later—without having to climb a ladder or use a tape measure, saving him time. “Our goal is to have [OpenSpace] on every project where we’re allowed to take photos,” Lucks said.

Learn how to use OpenSpace to create time-lapse videos of your project by clicking here.

Enhancing Communication, Increasing Productivity

Thanks to OpenSpace, Lucks does not need to visit jobsites in person as often, saving him as much as 10 hours of driving per week. Recently, OpenSpace eliminated the need for designers to fly in to visit a project, because U.S. Engineering’s Senior Project Manager Patrick Barnett pulled up OpenSpace captures during an owner, architect, and contractor meeting to address their questions virtually.

OpenSpace helps keep Lucks up to speed on progress at out-of-state sites he does not visit as often, so he can contribute more effectively. “Before OpenSpace, people would be calling me without me having any context,” he said. “It was definitely a lot harder.”

Reliable documentation from OpenSpace has also helped U.S. Engineering manage potential conflicts. When a general contractor recently provided a hard deadline for work completion, U.S. Engineering was able to demonstrate that another contractor had not completed their work, blocking U.S. Engineering from proceeding.

For more information, visit www.openspace.ai.