A&R Mechanical Contractors, Inc. credits PypeServer software with dramatically improving efficiency in its fabrication shop; pipe cutting tasks that used to take hours can now be done in 10 minutes or less. Justin Powers, A&R’s virtual design and construction (VDC) and fabrication business unit manager, oversees work across the spectrum from contract award to field installation. He described his company’s typical workflow and tools and the impact of integrating PypeServer software.

A&R’s VDC projects are detailed by tradespeople using Revit with Fabrication components. These VDC designers work closely with project superintendents to ensure that the model is accurate, constructible, and efficient. A coordination manager compiles clashes, runs meetings, and keeps the schedule, while also maintaining a single point of contact for a project. After sign-off, spooling is completed using BIMPro (from MSUITE), and exports are sent to PypeServer for nesting and pipe inventory. Lastly, spools are uploaded to FabPro (from MSUITE) for shop data and schedule tracking. A&R Mechanical uses a TigerStop cutting table for hangers and small-bore piping and an HGG machine for larger-bore steel piping.

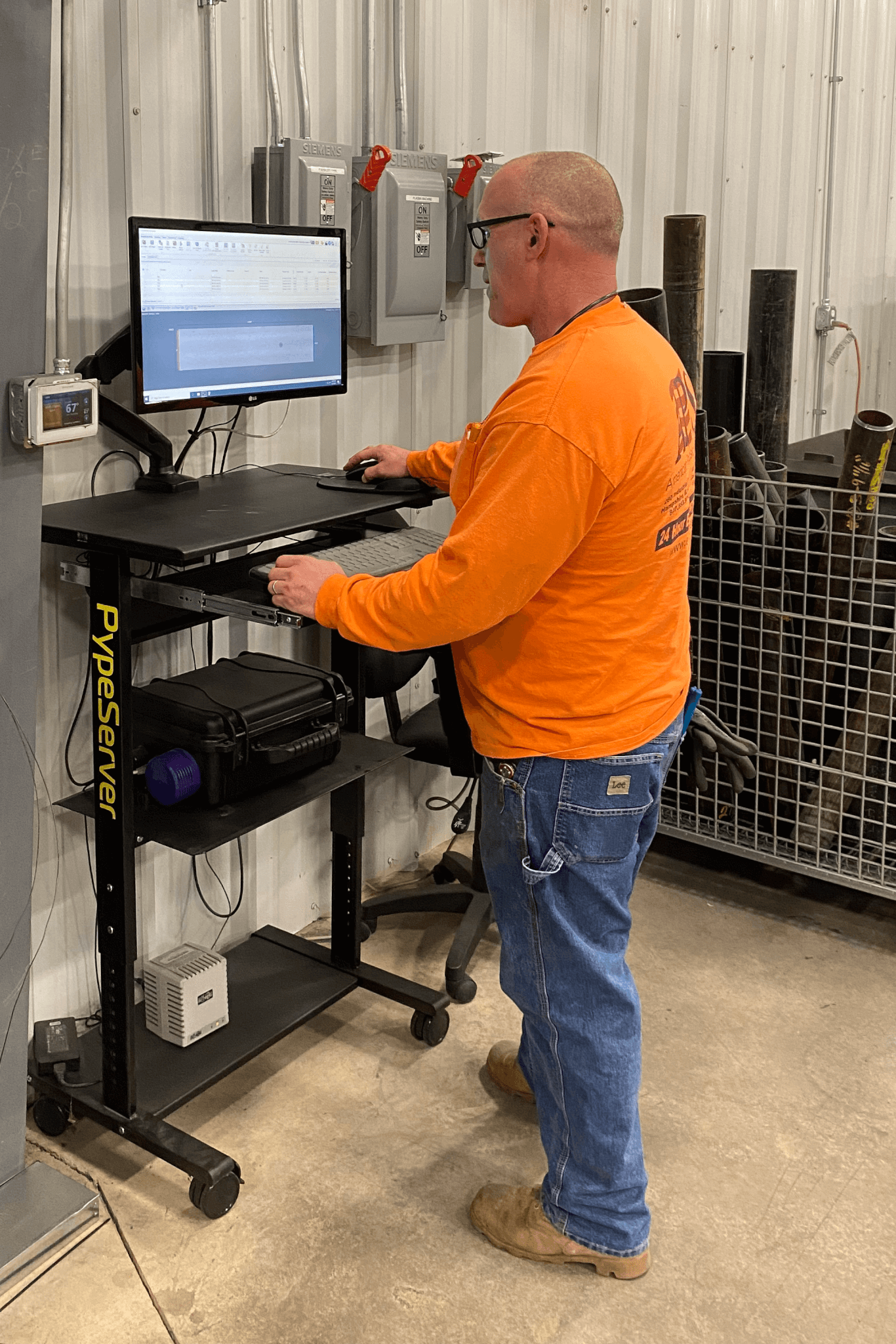

A&R selected PypeServer software for its interface and usability. Powers explained, “For us, the most crucial aspect of the software is usability. If the operator in the shop cannot operate the software reliably and without frustration, no amount of efficiency gained will be worth it in the long run.”

Powers noted that installing PypeServer was easy, but the learning curve was steep. “I believe this was due to being one of the first to utilize PypeServer with an HGG Machine,” he pointed out. With support from PypeServer’s staff, A&R got everything working as promised. “I have complete confidence that as new ideas and solutions are suggested, the PypeServer team will work with us to ensure that our machine is operating at peak efficiency and precision,” said Powers.

“With PypeServer, … tasks that took a couple of hours before can now be done in 10 minutes or less.”

— Justin Powers, VDC and Fabrication Business Unit Manager, A&R Mechanical

The effort has already paid off for A&R. “With PypeServer, the shop operator is no longer manually entering the pieces into the profiler,” Powers explained. “Instead, our exports are done efficiently and are stored on the machine for use at any time. Now, we can nest multiple spools and even whole projects on one piece of pipe. Tasks that took a couple of hours before can now be done in 10 minutes or less.”

PypeServer has proven to be an excellent value for A&R’s fabrication process. Powers pointed out some specific gains:

- The efficiency and speed with which the operator can begin cutting following spool assignment

- The availability of custom parameters, such as negative root gap (allowing A&R to lengthen a piece to account for a land being ground onto the pipe)

- The efficiency of nesting across multiple projects and spools

Powers acknowledged that being one of the first shops to integrate HGG machines with PypeServer software came with many bumps and challenges. Still, he credited the PypeServer team for putting in the extra time and effort to get A&R’s machine working as efficiently as possible. “PypeServer is a true innovator and leader in the space, and we couldn’t have done it without them,” said Powers.

For more information, visit www.pypeserver.com.