For those considering open-loop copper plumbing systems, there may be a misconception that bronze valves are the only reliable option for dezincification resistance. However, changes in lead-free requirements as a result of the Safe Drinking Water Act have led to new, viable alternatives to bronze. Heat-treated, dezincification-resistant brass valves are becoming a popular specified product within the engineering community. When subjected to ISO 6509 testing, heat-treated, dezincification-resistant brass valves perform as well as bronze in fighting against corrosion.

What Is Dezincification?

Many forms of corrosion can occur in copper-based alloys. The most common in plumbing systems is dezincification. This process mainly exists in copper zinc alloys that contain more than 15 percent zinc. Dezincification selectively removes zinc from an alloy, leaving behind a porous and copper-rich structure with poor mechanical strength.

Additional environmental factors can also contribute to the acceleration of dezincification. These factors include water with high levels of oxygen and carbon dioxide, slow-moving (or stagnant) water, water with high chloride ion content, and water with high salt content above room temperature.

In some instances, design engineers and contractors are unaware of harsh, preexisting conditions prior to beginning work onsite. However, after completion of a piping system, a number of visual signs might indicate a higher likelihood of dezincification in common copper alloy valves. These indicators include mineral stains on the outer surface of a valve, water weeping from a valve body or stem seal, and the presence of a white deposit (zinc oxide) on the exterior of the valve. A narrowly written valve specification can help minimize these potential failures by simply calling for a proper corrosion-resistant, copper-based alloy.

How Can Brass Become Corrosion Resistant?

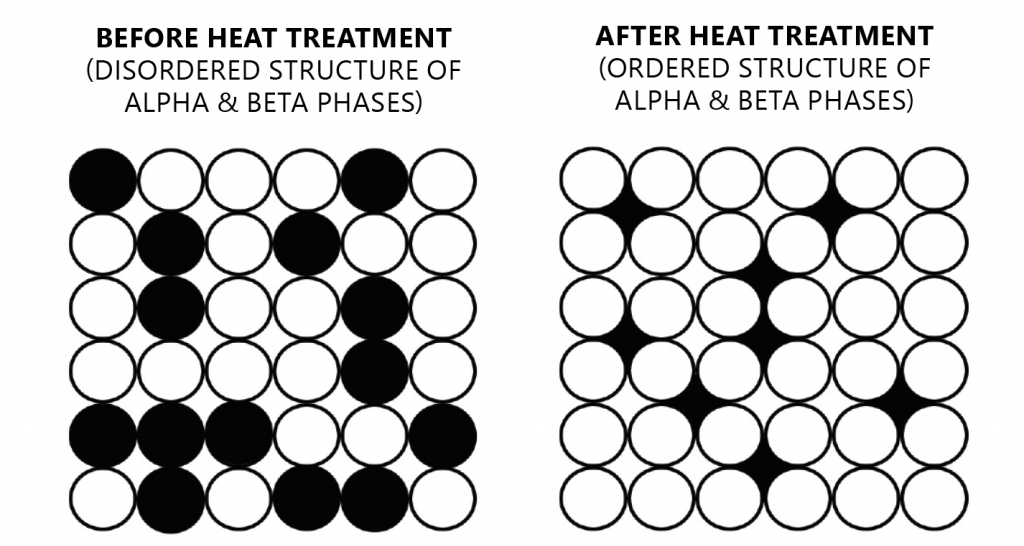

Two manufacturing methods can eliminate dezincification in copper-based brass alloys. The first method is to increase the copper content, which results in a reduction of zinc in the alloy. The second practice involves adding corrosion inhibitors to brass alloys. Only through a controlled-heating and slow-cooling annealing treatment can the second method create a stronger material with a realigned molecular structure. Brass alloys typically have two phases to their molecular structure. The first—alpha phase—is dezincification resistant; the second—beta phase—is dezincification susceptible. When brass alloys are enhanced to an all-alpha phase through heat treatment, they perform the same as bronze alloys when fighting dezincification.

The Solution: Heat-Treated Forged Brass

An example of a heat-treated alloy in the commercial plumbing industry is CW511L. This duplex brass is a lead-free brass alloy composed of both an alpha and beta phase. Alpha and beta phases correlate to the solubility between metals in brass alloys, resulting in different colors and structures in each phase. As a result of the temperature changes in heat treatment, elements within the alloy change their liquid and solid states, resulting in a restructured alloy composition.

The alpha and beta composition is resistant to cracking and is extremely malleable at high temperatures. The purpose of heat treatment is to transform alpha and beta phases into a predominately alpha phase (dezincification resistant). After heat treatment, the new composition structure’s alpha-to-beta-phase ratio is less than one percent beta phase, resulting in a dezincification-resistant alloy. At this point, beta phase is now referred to as a residual beta phase, and the alloy structure is 99 percent in alpha phase. This restructuring leaves a brass alloy that is now truly dezincification resistant.

Figure 1 (below) shows the varying phase changes of CW511L during the heat treatment process. These changes are distinguishable by the color and shape of the crystals within the alloy. When the alloy completes its heat treatment process, the color of the brass will appear more gold than bronze under a microscope. However, the valve body surface will appear bronze in color due to the oxidation of brass at 1,000° F (537.87° C).

When CW511L brass is heated to a temperature of 1,000° F (537.87° C), an all-alpha phase is achieved. This alpha state is maintained in the alloy by a slow-cooling, annealing process. The end result is optimal dezincification performance when tested to the ISO 6509 standard for determining dezincification depth of copper alloys with zinc exposed to fresh, saline, or drinking water. The method is intended for copper alloys with a mass fraction of more than 15-percent zinc.

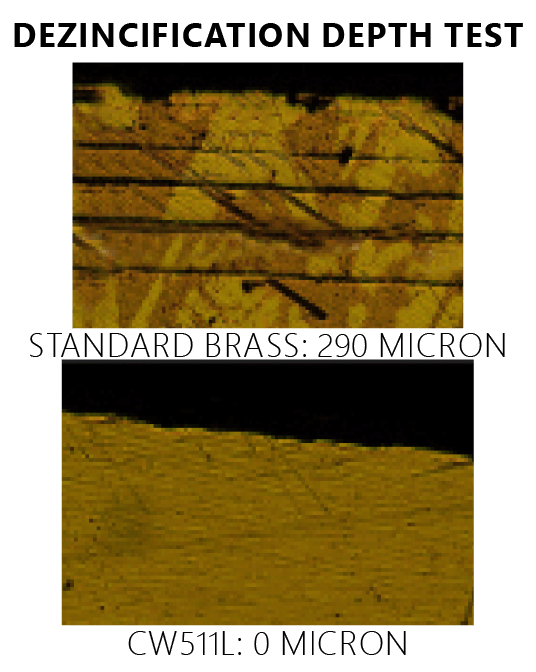

Third-party ISO 6509 testing explored dezincification susceptibility among copper-based alloys, including bronze and brass valves. This testing illustrated the difference in dezincification depths for each valve and corresponding alloy. It was determined that heat-treated CW511L brass showed a dezincification depth of zero microns, which was equivalent to the dezincification depths seen in bronze valves. The remaining non-heat-treated brass valves showed dezincification above 200 microns depth as illustrated in Figure 2 (below).

This level of dezincification is above the acceptable performance level based on the ISO standard, deeming the non-heat-treated brass valves as not truly dezincification resistant. The results of the test prove that not all brass materials are equal and that certain heat-treated brass alloys can perform as well as bronze when it comes to corrosion resistance.

Jomar Valve’s white paper offers more detail on dezincification: https://www.jomarvalve.com/docs/lit-wp-crb.pdf

Consider Alternatives

Dezincification in plumbing systems is an ongoing battle, but bronze is not the only solution. New technologies, like Jomar Valve’s heat-treated CW511L brass alloy, can act as a combatant to dezincification while providing an increased level of mechanical strength.

For more information, visit www.jomarvalve.com.