Advances in Oil-Free Compressors: Copeland Explains

In the air- and water-cooled chiller markets, oil-free compression technology is emerging as a more efficient, quieter, more easily applied, and easier-to-maintain alternative to legacy screw compressors. For original equipment manufacturers (OEMs) and end-users of mission-critical chillers in large HVAC applications, oil management adds costs and complexities to system designs—which typically result in declining energy efficiencies throughout their lifecycles.

Currently available oil-free compressors rely on costly magnetic levitation (maglev) bearings, which tend to decline in performance in warm climates and complicate system design. In recent years, environmental regulations and sustainability initiatives have driven design changes in air-cooled chillers. OEMs and industry stakeholders are pursuing the next generation of oil-free compression technologies that can achieve high operating efficiencies and simplify application complexities while supporting the imminent transition to lower global warming potential (GWP) refrigerants.

Emergence of Oil-Free Compression

Air- or water-cooled chillers provide essential cooling—and heat recovery in many cases—in data centers, health facilities, and other large buildings. Because of the high-tonnage cooling requirements of these applications, large screw compressors have traditionally been deployed. While reliable and robust, screw compressors pose oil management challenges:

- Maintenance and upkeep costs and requirements

- Declining energy efficiencies and performance over time

- Increased risk of performance degradation and potential chiller failure

In recent years, air-cooled chillers have been adopted, primarily in response to concerns about water availability and sustainability. Although an air-cooled chiller with screw compression and a flooded evaporator can deliver efficiency gains, the need for oil return and management mechanisms significantly increases system design complexities. A similar system designed with an oil-free compressor can provide the same performance benefits without the added oil management complexities, conserving water and reducing environmental impacts while improving application reliability.

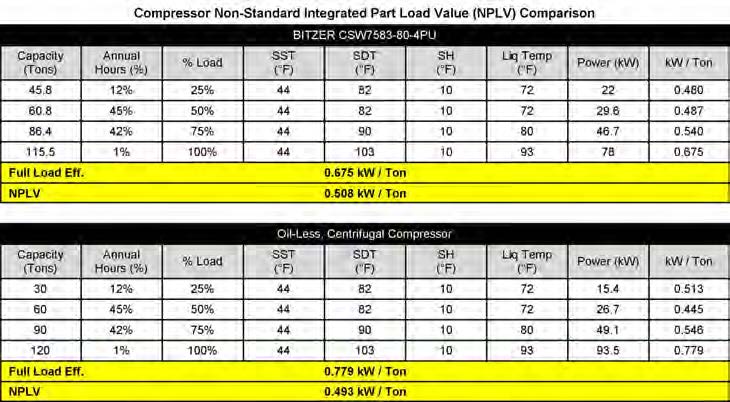

The annual energy consumption of an air-cooled chiller is an important factor in determining both lifecycle costs and sustainability footprint. Chiller and compressor selection starts by matching a building’s cooling load with chiller capacity. Then, the system’s lifecycle costs or return on investment is calculated, including estimated operational and maintenance costs.

Air-cooled chiller and oil-free compression solutions deliver the highest possible energy efficiencies without sacrificing reliability or introducing unnecessary operational complexities. Compressor modulation technologies can provide significant efficiency gains over the operating envelope and allow precise load matching in both full- and part-load conditions. Moreover, an air-cooled chiller solution can achieve these goals in some of the most demanding design conditions, such as the high-lift, warm-climate cooling load requirements found in many data center installations.

With the global phasedown of hydrofluorocarbon (HFC) and high-GWP refrigerants, the HVAC industry is moving toward new, lower-GWP refrigerant alternatives. The Environmental Protection Agency has set a maximum GWP of 700 for the chiller sector, which will drive the market toward emerging A2L alternatives—many of which have lower flammability designations under ASHRAE classifications.

Upgrading Existing Technology

Today’s oil-free compressors, designed with maglev technology, require multiple permanent electromagnetic bearings to levitate the compressor rotor (i.e., shaft). Radial and axial proximity sensors are needed to regulate the position of the rotor, and sophisticated, on-board, compressor controls are required to maintain reliable, frictionless operation. In the event of a power disruption, the compressor is no longer energized, and standard auxiliary (nonmagnetic) bearings are needed to maintain low-speed operation. This inherent design feature can increase compressor costs and application complexities.

Oil-free compressors with maglev bearings can experience performance-related limitations:

- Insufficient envelope range for high-lift conditions (i.e., significant cooling in high ambient temperatures)

- Reliability concerns and efficiency loss in part-load, turndown conditions

- Prone to surging (i.e., flow reversal) and choking (i.e., maximum flow) in stop/start conditions

- Short cycling, which can impact cooling performance

Current oil-free technology relies on the integration of a compressor, on-board controls, and a variable frequency drive. But this preconfigured architecture can present design customization challenges for OEMs who are unable to decouple the compressor from the controls and drive. In hot, humid climates, for example, this inflexible architecture could result in on-board electronics issues—potentially increasing maintenance, threatening operational reliability, and limiting chiller applicability.

Oil-free centrifugal technologies are raising the standards for chiller performance—delivering high-lift reliability, improved efficiency and sustainability, and a broader application range for the next generation of air- and water-cooled chillers. For example, Copeland’s oil-free centrifugal compressor leverages frictionless Aero-lift™ bearing technology to optimize energy efficiency, simplify design complexities, and maximize the performance of air- and water-cooled chillers in demanding conditions—and in full- or part-load cooling scenarios. Aero-lift bearings enable the Copeland oil-free centrifugal compressor to operate independently—without reliance on electromagnetics, proximity sensors, and complex controls. Compared to existing screw compressor technology, the Copeland oil-free centrifugal compressor delivers significant energy efficiency gains in full- and part-load conditions.

For more information, visit www.copeland.com.