By swapping out Excel spreadsheets for MSUITE software across multiple fabrication shops, McCarl’s Industrial and Mechanical Contractors now has real-time visibility into their workflow, not the two-to-three-day lag time. Adopting a fully digital platform has optimized workflows and increased operational efficiency.

McCarl’s is known for their expertise in complex heavy industrial services and pipe fabrication across various sectors. The collaboration between McCarl’s fabrication management team—led by Jon Bushmire, operations manager, and Max Wimer, project engineer/project manager—and the team at MSUITE, has significantly improved their operations. MSUITE provides McCarl’s with real-time visibility, optimized design-to-fab workflows, and enhanced quality-control (QC) capabilities.

McCarl’s implemented MSUITE across two of their three fabrication shops. Each shop covers 60,000 square feet, and McCarl’s employs about 50 fab shop workers. They use Autodesk’s AutoCAD Plant 3D toolset to send designs to both shops. Integrating Power BI with MSUITE supports enhanced assignments, visibility, and tracking.

According to Bushmire, implementing MSUITE came with the typical challenges of new software adoption, but it has been a success, particularly due to the instrumental role of team members like Wimer. “As we grow, we’ve found the system to be very user-friendly and centralized. Our design and drafting departments are in one area, making it easy to create and distribute drawings to the fab shops. This has streamlined working on the same project across multiple shops, reducing confusion,” said Bushmire.

A recent example involved a job that started in the Beaver Falls, PA, shop but had to be moved due to overflow. Tasks were seamlessly reassigned to another shop with all necessary drawings and welds in place, demonstrating the system’s efficiency and ease of use.

To learn more about how McCarl’s and others are gaining a competitive advantage with MSUITE, read 5 Tips for Optimizing Your Fabrication Operations here: https://www.msuite.com/5-tips-for-optimizing-your-fabrication-operation/

Dashboard Highlights Progress

Integrating MSUITE with Power BI yields a dashboard that provides McCarl’s a comprehensive overview of activities across two fabrication shops and one design team. It allows for easy monitoring of completed stages, tracking the delivery status of items, and determining the next steps for field teams.

McCarl’s can share the dashboard with clients for better transparency, and reports can be easily exported to provide stakeholders with clear visibility into a project’s status—whether it is a project McCarl’s is fabricating for their own job or for others’, as they occasionally do, Bushmire said. For example, reports can show:

- fabrication projects in process;

- items in the QC process;

- items scheduled for delivery; and

- Items that have been delivered.

Life Before MSUITE

Before implementing MSUITE, McCarl’s used an internally developed Excel spreadsheet to track activities. According to Bushmire, Power BI closely mirrors their old spreadsheet, which made the transition smoother. They utilized this template to pull information into Power BI, maintaining a familiar format for their field teams.

Excel and manual tracking pose several challenges:

- Limited access: Only one person could use the spreadsheet at a time, leading to inefficiencies.

- Data integrity issues: Multiple users caused data duplication, deletion, and inconsistencies.

- Manual updates: Tracking and updating information manually was cumbersome.

Using MSUITE and Power BI allowed McCarl’s to overcome those challenges:

- Database reliability: The database handles fabrication data management, helping provide accuracy and consistency.

- Immutable reports: Power BI allows view-only without manipulation, preserving data integrity.

- Automatic updates: Users can simply refresh the data to get the latest updates without manual input.

“From a management perspective, the real-time visibility provided by MSUITE is invaluable,” said Bushmire. “Previously relying on outdated Excel spreadsheets, the team now benefits from up-to-the-minute data, significantly enhancing their ability to manage fabrication status.” Immediate access to current information is crucial for effective management and decision-making. In addition, MSUITE’s user-friendly interface ensures that everyone, regardless of tech experience, can operate the system easily using tablets.

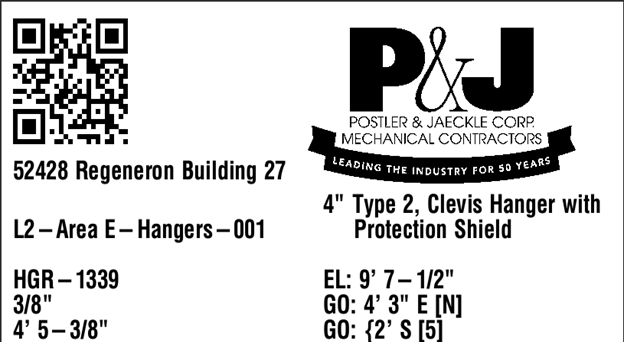

Attention to Detail

Wimer pointed out, “MSUITE has revolutionized the QC Department by automating the generation of quality documents, which previously required manual input. This automation allows the QC team to make final adjustments and send documents to clients quickly. Our fitters and welders enter heat numbers, select weld procedures, and claim welds completed instantly.”

Wimer noted that MSUITE has streamlined the design-to-fabrication process, especially when releasing drawings to the shop, further enhancing operational efficiency. He also appreciates the close collaboration with MSUITE. “The regular bi-weekly meetings with the MSUITE support team foster a strong partnership. These meetings ensure the software is continually improving and address any immediate issues.

“We’re also working with MSUITE to develop more features tailored for industrial pipe fabricators like us. Our business is very dynamic, given the nature of industrial piping,” said Wimer.

Bushmire added, “In industrial fabrication, tracking every detail is crucial. We need to know the heat number, chemical makeup of the steel, welding procedures, who welded it, and the results of X-ray tests.

“There’s a lot of information to manage. Unlike some types of commercial work, which may not require such extensive tracking, industrial fabrication demands it. For less complex fabrication tasks, I think MSUITE works perfectly, but for intricate levels where tracking is essential, it’s a vital tool,” Bushmire continued.

Industrial Fabrication Trends

Bushmire and Wimer agree that the industry is rapidly advancing toward the adoption of new technology, including robotics in welding. Bushmire noted that while every fabricator has their own way of doing things, technological systems greatly enhance efficiency. “Implementing new technology is a significant task and doesn’t happen overnight,” he said. It took McCarl’s about a year to fully integrate and optimize their new MSUITE system.

Bushmire emphasized the importance of ensuring that new systems can integrate seamlessly with robotics and stay updated with the latest technology. As more fabricators adapt to new technology, maintaining pace with these advancements is crucial.

“In our pipe fabrication, the Rotoweld is our most advanced robot. From my visits to the Pipe Fabrication Institute, I’ve become well-acquainted with two industry-leading robots: the Novarc and the Rotoweld. Both are excellent, each with unique strengths suited to different types of fabrication,” said Bushmire.

Impact in the Fab Shop

Wimer reports that staff at various shops find MSUITE comprehensive and easy to use, making their tasks straightforward and satisfying. Bushmire emphasized that the utility of MSUITE depends on the scale of operations. “For high-volume fabrication, tracking thousands of welds each month, MSUITE is essential.”

The new process, combined with tools created in Excel, has significantly streamlined operations at McCarl’s. “We’re just a couple of clicks away from getting 20–30 drawings in,” said Bushmire, noting the immense time saved compared to the previous manual spreadsheet method.

While Excel might work for a single job, McCarl’s found it was not feasible for managing multiple simultaneous projects. Bushmire advises fabricators looking to grow and manage multiple shops seamlessly to consider MSUITE. “As McCarl’s expands into new areas like Nevada, Oregon, and North Carolina, using a system like MSUITE is crucial for ensuring seamless operations across various locations,” he said.

For more information, visit www.msuite.com.