To meet the tight timeline for a new multimillion-dollar casino and hotel, The Severn Group leveraged the Victaulic grooved copper system’s design flexibility and on-site fabrication capabilities to manage the project’s most critical aspects. As a result, The Severn Group was ahead of schedule on every portion of their scope of work. Victaulic is a major sponsor of MCAA24.

No Time for Delays

Dumfries, a small town in Virginia with a population of approximately 5,750, will soon be home to the Rose Gaming Resort, a $372-million gaming and entertainment complex. The highly anticipated facility is expected to generate the town $35.5 million in annual tax revenue. It will have more than 50,000 square feet of gaming casino, luxury hotel, dining, and event space. Owners made speed to market a priority for the project, trusting that their construction partners would meet the intended completion date, even when the project experienced a start delay.

The Severn Group installed the heated, chilled, and domestic water systems, as well as the mechanical room and plumbing throughout the casino and hotel. “Because the casino is built on a former landfill, preparatory site work delayed the construction schedule for two months—but the owner’s target completion date remained the same. We had to come up with ways to speed up our construction process,” said Richard Grasso, director of operations at The Severn Group.

Grooved Pipe Minimizes Schedule

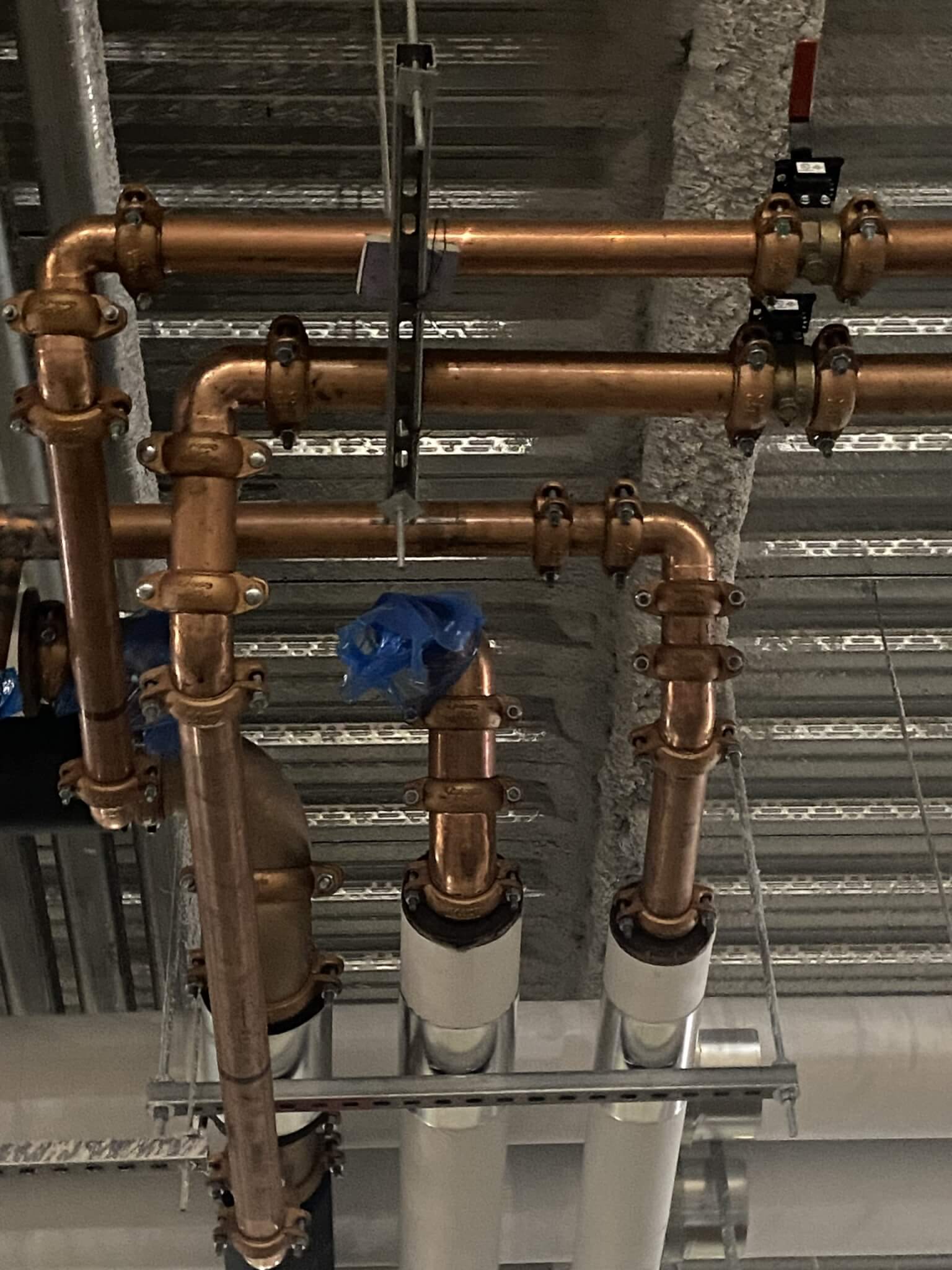

Among the challenges was streamlining the installation of 2”- to 6”-diameter copper pipe in 35’-tall ceilings in tight corridor spaces. According to Grasso, The Severn Group’s traditional standard is to solder or braze copper tube. However, the project’s time crunch required a deviation from their traditional strategy. The Severn Group only had a small crew available to perform the sizable installation at Rose Gaming Resort and needed to consider how their joining method would impact the MEP trades working around them.

“Trades in these projects are first-come, first-served. Coming second means working around the trades that arrived before us, but it didn’t matter because we used Victaulic. All we needed was to get a scissor lift and a worker to the area, whereas with brazing and soldering, we might not have been able to get around the other trades,” Grasso said. “Victaulic helped ease the stress. We didn’t have to worry about mirror welding, burn permits, hot work orders, fire watch, cordoning off spaces, or welding screens.”

The Severn Group used Victaulic Style 607 QuickVic™ Installation-Ready™ couplings, fittings, and valves to build the copper domestic water system. The products are specifically designed for domestic water applications and are resistant to potable water disinfectants. The Installation-Ready technology is delivered preassembled with no loose parts, meaning contractors only need to stab couplings on pipe ends and tighten bolts to secure them.

According to Grasso, The Severn Group gained back 10 days on the schedule by using Victaulic in the corridor and setting up on-site grooving stations despite working with a smaller crew than originally expected. As additional workers were brought on to expedite the project, they could begin installing grooved copper tube confidently following short training sessions, thanks to easy-to-use products.

“We are creatures of habit and resisted embracing a full Victaulic copper system for a long time,” said Grasso. “Rose Gaming Resort changed that. It’s in Severn’s standards that Victaulic copper is a go. We’re 100-percent sold. I have no doubt that this system will run for as long as the owners want it to.”

Powered by On-Site Fabrication

The Severn Group did not have shop drawings available for all of the spaces, meaning they would need to capture field measurements, contact their off-site fabrication team, and wait for shipments to arrive before installation could begin. On-site fabrication became key to project success. By setting up a Victaulic grooving tool on the jobsite, The Severn Group achieved considerable time and material cost savings while remaining nimble enough to adapt to unforeseen changes.

“Coordination was under the gun the whole time. We couldn’t afford to lose time waiting for pieces to get fabricated and delivered. We would show up to the site and need to get pipe installed immediately, which is why we switched gears,” Grasso said. “We redlined the drawings as we received them, making changes and adjustments to navigate jumping over ductwork, conduits, and everything else on the fly.”

The Severn Group’s crews set up a Victaulic RG4300 roll grooving tool adjacent to their work area to make it as efficient as possible to prepare, cut, and groove pipe pieces. Thanks to the tool’s compact design, it is easy to transport, and The Severn Group always had the grooving station near work areas, even as they progressed throughout the expansive facility. Victaulic’s roll grooving tool also reduces the risk of error and rework time with a depth-setting feature that enables users to create quality, consistent grooves every time.

Winning Time on the Roof

The Severn Group significantly reduced schedule times on the rooftop, where they were able to complete 20 air handling units in half the time allotted by prefabricating with Victaulic products. Unlike other pipe-joining methodologies, mechanical joints can be easily disassembled when there are misalignments, effectively minimizing lost time in the event of rework. During the time-sensitive Rose Gaming Resort project, The Severn Group’s crew did not need to recut, reweld, or rely on a crane to lift additional materials to the roof when adjustments were needed.

“We had 16 hours scheduled per air handling unit; we cut that down to eight in the shop. On the roof, Victaulic gave us the ability to adjust the design in a matter of minutes,” Grasso said. “It was a conscious decision to mitigate risk and make up time.”

The Severn Group “resisted embracing a full Victaulic copper system for a long time. Rose Gaming Resort changed that. … We’re 100-percent sold.”

—Richard Grasso, Director of Operations, The Severn Group

Partnership Drives Success

Construction on the Rose Gaming Resort is still underway, with an anticipated completion date in 2024. All components in the hotel and casino have been hydrostatically tested and signed off on in the promised time, an accomplishment that Grasso attributed to the collaboration everyone demonstrated.

“We don’t have people we buy from. We have partners, and Victaulic was a huge partner to us. Everyone worked as a team with the same goal in mind. There was no pushback, just a ‘What can we do to help?’” Grasso said.

For more information, visit www.victaulic.com. MCAA thanks Victaulic for being a major sponsor of MCAA24 and co-sponsoring the annual golf tournament at the Ritz Carlton Golf Club.