Simplify Tagging, Save Time Featuring Marking Services Inc.

An energy company in the Southeast teamed up with Marking Services Inc. (MSI) to replace its outdated labeling systems across their electricity generating plants, saving time and labor. Working closely with the company, MSI developed a standardized labeling system to help with safety, compliance, maintenance, and emergency response at the company’s many plants (including solar and hydroelectric facilities). As a result, the company implemented a labeling and asset management program using more than 500,000 labels. MSI’s field team ensured proper and precise installation, which in turn saved the energy company time and labor.

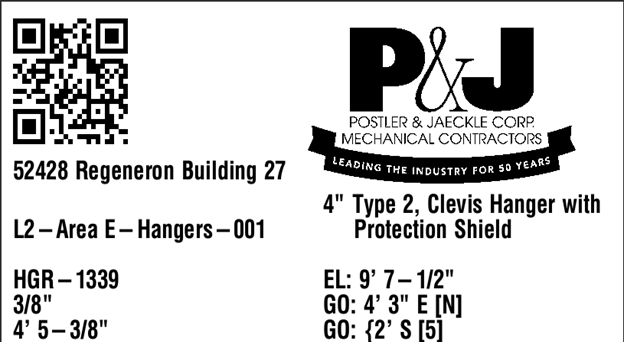

Through a collaborative process, MSI tailored products to the company’s needs, including more than 5,000 custom MS-215 Rigid Thermoplastic QR-coded process safety management tags designed for specific environments. The durable tags are engineered to withstand harsh conditions, including high heat, fierce winds, and exposure to dust from materials like limestone and gypsum.

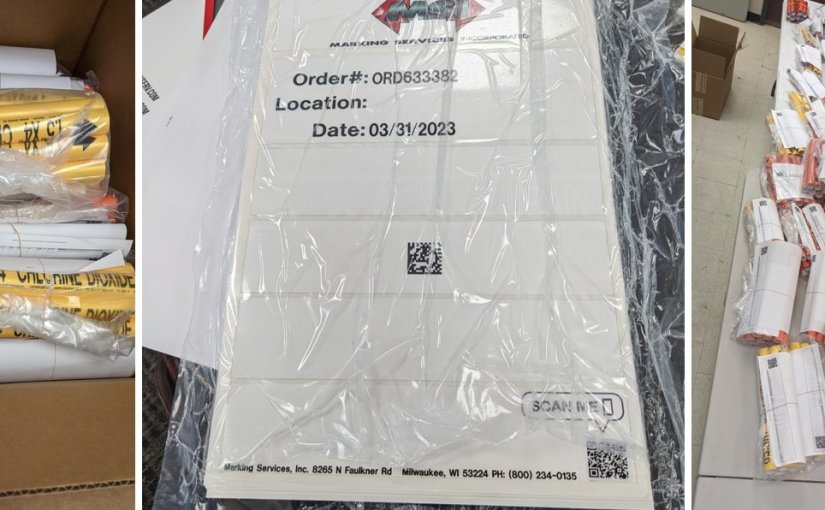

MSI’s Material Take-Off service reviews project drawings in detail to identify exactly where each label needs to go and create a precise bill of materials. Labeling materials are delivered to the jobsite meticulously packaged by MSI based on the drawing, building section, or even specific rooms, so the team can immediately install the right labels in the right places. Clients also receive access to the marked-up drawings on their mobile devices, enabling real-time, on-the-go reference to ensure nothing is missed.

The MSI approach saves hours in planning and labeling and significantly reduces the risk of errors, avoiding costly rework and delays. The energy company found that partnering with MSI freed up time to focus on the bigger picture of completing projects.

Read MSI’s blog, 4 Signs It’s Time to Replace or Upgrade Your Labels, here: https://www.markserv.com/blog/4-signs-its-time-replace-or-upgrade-your-labels

MSI’s Valve Schedule Service simplifies valve tagging and includes essential components such as valve identification, type, service description, system abbreviations, valve number, level or area, operating positions (open, closed, or modulating), maintenance information, and safety information. MSI provides custom-manufactured tags meticulously organized according to project-specific drawings, room designations, or designated areas.

Learn about Marking Services Inc.’s mechanical pack-by services: https://youtu.be/NgIEpmamrH8?si=ijKWTfmIBjw2lB-x

The collaboration between the energy company and MSI highlights how tailored solutions drive substantial improvements, reinforcing that efficiency and safety are paramount in today’s fast-paced energy sector.

For more information, visit www.markserv.com.