NuFlow Midwest, in partnership with Althoff Industries, successfully completed a large-scale pipe rehabilitation in a 60-story Chicago high-rise by using NuFlow Technologies’ cured-in-place pipe lining (CIPP) for hard-to-reach pipes, avoiding costly, disruptive removal and preserving vital building systems. This minimally invasive solution enabled Althoff and NuFlow to comply with Chicago’s building codes while preserving surrounding mechanical systems and reducing downtime in shared spaces.

A Tall Order

The mixed-use high-rise, located in downtown Chicago, comprises 24 floors of commercial office space beneath 35 floors of residential units, where significant issues with leaks and sludge buildup were affecting lateral lines and kitchen sanitary mains. The pipes were part of an intricate system running throughout the building, entwined with other mechanical systems, with some sections encased in concrete slabs within shared gym and pool spaces.

Though only 30 years old, the building’s cast iron piping system was deteriorating, with degraded pipes and sludge accumulation along the exterior. An engineering firm identified the source: gases produced by food waste from garbage disposals in residential units were corroding the pipes. Access to the pipes was complicated by their entanglement with the building’s electrical, HVAC, and fire protection systems, as well as their encasement in concrete. Traditional replacement would have required dismantling sections of these systems, resulting in extensive downtime and significant costs. The commercial office spaces below, unaffected by the plumbing issues, needed to remain fully operational throughout the project. Minimizing disruption to commercial tenants and residents was a priority, and NuFlow Midwest and Althoff’s solution needed to align with the project’s tight timeline.

NuFlow Midwest and Althoff proposed NuDrain CIPP, allowing for in-place pipe rehabilitation without the need for removal. This approach preserved surrounding structures and minimized downtime, making it the ideal choice for the building’s unique requirements.

NuFlow Midwest and Althoff specialize in advanced pipe rehabilitation solutions, offering a blend of conventional pipe replacement and trenchless lining techniques to address aging infrastructure. This project allowed NuFlow Midwest and Althoff to showcase the advantages of their combined approach, balancing CIPP lining for hard-to-reach areas with traditional pipe replacement in more accessible spaces. Their unique expertise enabled a unique solution tailored to the demands of the high-rise project, and they collaborated closely with the project’s general contractor and engineering firm.

What’s the difference between pipe lining and pipe coating? Read this blog: https://nuflow.com/blog/pipe-lining-vs-pipe-coating/

Trenchless Technology

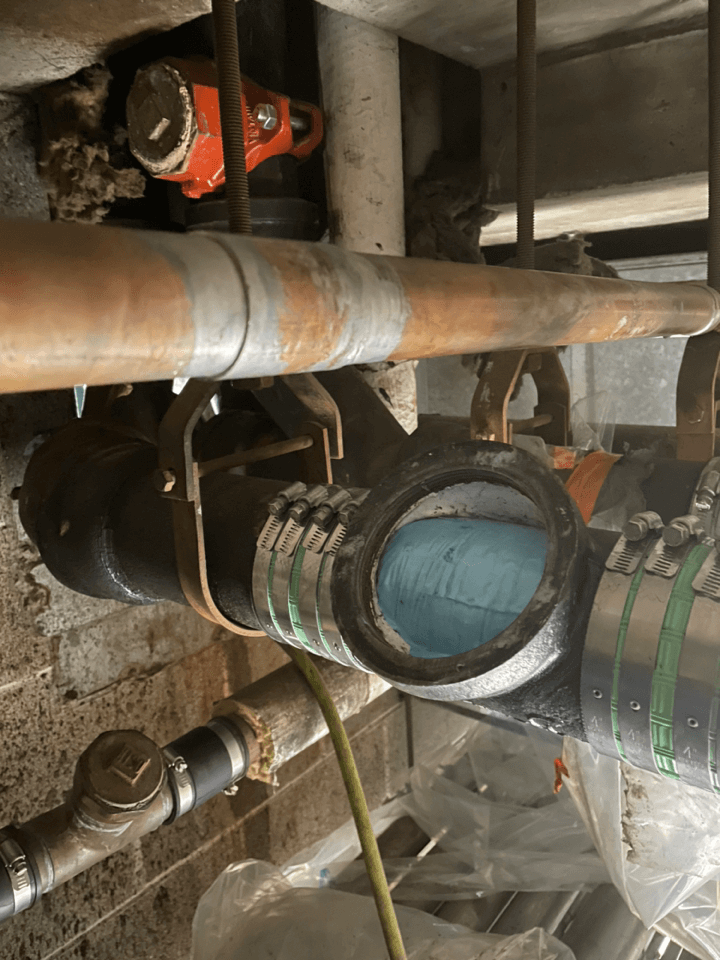

NuFlow Midwest and Althoff lined 510’ of 4”, 265’ of 5”, 105’ of 6”, 75’ of 8”, 85’ of 10”, and 100’ of 15” piping using NuDrain CIPP trenchless technology. This approach was especially effective for pipes buried deep within the building structure. In accessible areas, such as mechanical rooms, the team prelined and installed 100’ each of 6” and 8” cast iron pipe, enhancing durability to prevent future deterioration.

To address fittings, the team employed a combination of the “gap” method and mechanical reinstatements. Using a pull-in-place technique, liners were precisely installed to start or stop at each fitting, overlapping the joints, leaving a gap to preserve the branch connection. This method is ideal when access to the branch is not possible for immediate reinstatement, allowing for future rehabilitation with a specialized “connection” liner when the property is ready for that phase. Additionally, approximately 30 prelined 4” cast iron cleanouts were installed to facilitate ongoing cleaning and maintenance. This approach minimized disruptions, enhanced system reliability, and ensured smooth transitions between lined and unlined sections.

Strategic scheduling played a key role in maintaining tenant convenience. NuFlow Midwest and Althoff coordinated shutdowns only during standard work hours, limiting disruptions for residents and ensuring that commercial office spaces remained fully operational. A detailed daily schedule was provided to all residents, minimizing confusion and fostering transparency.

Minimizing Time, Disruption, and Costs

The project was completed over two to three months during the summer, delivering substantial savings and minimal disruption to building tenants. By rehabilitating pipes in place rather than removing them, NuFlow Midwest and Althoff preserved critical building systems and avoided costly and invasive dismantling of electrical, HVAC, and fire protection systems. With well-planned scheduling, the residential tenants experienced minimal inconvenience, while the commercial offices continued operations without interruption. This effective coordination not only saved the general contractor time and money but also contributed to high satisfaction levels for the building’s HOA and its residents.

NuFlow Midwest and Althoff’s combined use of CIPP lining and prelined cast iron sections resulted in a robust, low-maintenance pipe system for the building. Since project completion, no issues have been reported, and both the HOA and general contractor expressed satisfaction with the outcome, citing significant cost savings, seamless project management, and long-term durability.

This project highlights NuFlow Midwest and Althoff’s expertise in delivering innovative, effective pipe rehabilitation solutions for complex, high-rise urban settings. Through careful planning, regulatory compliance, and strategic project execution, NuFlow Midwest and Althoff provided a sustainable solution with minimal impact on residents and commercial tenants, reinforcing their leadership in trenchless pipe rehabilitation for complex projects.

For more information, visit nuflow.com.