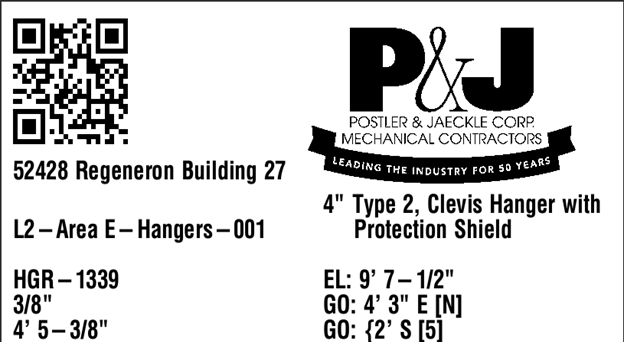

Labels have traditionally been used in construction to convey basic information, but Postler & Jaeckle Corp. is applying Stratus labels and weld maps to transform their practices, so their teams work smarter, not harder. Jesse Gorman, vice president at Postler & Jaeckle, recognizes the potential for using labels to communicate more detailed, actionable data. His goal is to build directly from the labels, an approach that maximizes their utility in conveying essential information for installing components accurately, boosting his team’s efficiency. Using technology from Stratus, data are extracted and printed onto labels, providing teams with easy-to-understand guidance onsite.

Although labeling is a familiar tactic, Gorman believes that more effective implementation can bring significant changes in workflow efficiency. Integrating grid offset information allows workers to know exactly where each component should be placed, akin to how ironworkers label steel pieces on a construction site. This approach helps eliminate guesswork, ensuring components are installed correctly and swiftly.

See examples of how customers are using Stratus to generate company-, content-, and even tool-specific labels for their MEP parts, hangers, packages, and containers with QR codes for tracking and customizable information for installation: https://www.stratus.build/labeling

Innovation and Efficiency

In another innovative step, Postler & Jaeckle is introducing continuation labels. This type of labeling goes beyond the conventional A-to-A, B-to-B matching by using existing data to show the next assembly’s connection, thanks to Stratus’s capabilities. This efficient system saves time and reduces errors, providing clear orientation for each assembly.

Postler & Jaeckle is also testing task labels in weld booths to streamline processes. By integrating Zebra printers in these stations, completed tasks such as fabrication automatically update the project’s status, producing labels instantly. This ensures that all components are accurately tagged and traceable, facilitating a more seamless workflow from workshop to site.

Weld maps play a critical role in maintaining accuracy during field installations. Postler & Jaeckle uses a package category system within Stratus to track welds, aligning these with project test boundaries. This comprehensive tracking ensures that documentation is thorough and organized, which is vital for successful project completion.

Postler & Jaeckle recognizes the importance of standardization to increase efficiency. Implementing kits and predefined packages for commonly used components ensures that project teams can spend less time sorting materials and more time installing them. Gorman pointed out the potential in moving away from traditional sequences by attempting to install hangers and pipes simultaneously, which, although still in experimental stages, shows promise for future projects.

Hear more about how Postler & Jaeckle and other contractors are using Stratus to streamline operations: https://www.stratus.build/insights/why-contractors-are-using-stratus

Embracing Attitude Shifts

The construction industry is full of seasoned professionals who may be resistant to change, but as Gorman noted, adopting new practices often depends more on attitude than age. By focusing on efficiency, simplifying workflows, and leveraging technology, construction teams can achieve higher productivity levels, marking a significant shift in how projects are executed.

Postler & Jaeckle Corp.’s journey through these innovations showcases how even small changes, like improving label usage and systematizing weld maps, can have a significant impact. These advancements make it easier for teams to complete tasks accurately while ensuring the safety and reliability of the build. As the industry continues to innovate, those who are willing to embrace these changes will undoubtedly find themselves at the forefront of the next generation of construction practices.

For more information, visit www.stratus.build.