Dick Starr, Former MSCA Chairman, Provides Insight on the Maintenance Requirements of High-Performance Buildings

Energy efficiency, comfort, and productivity are the top focus for most high-performance buildings, according to Dick Starr, senior account executive, Enterprise HVAC Service & Control, Twinsburg, Ohio and former chairman of the MSCA Board of Managers.

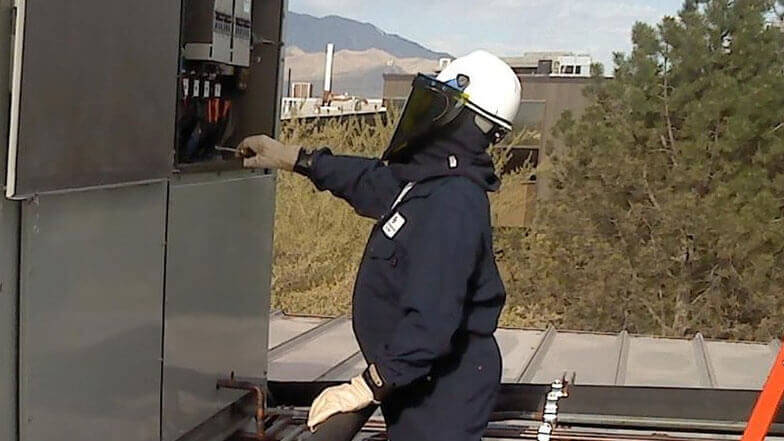

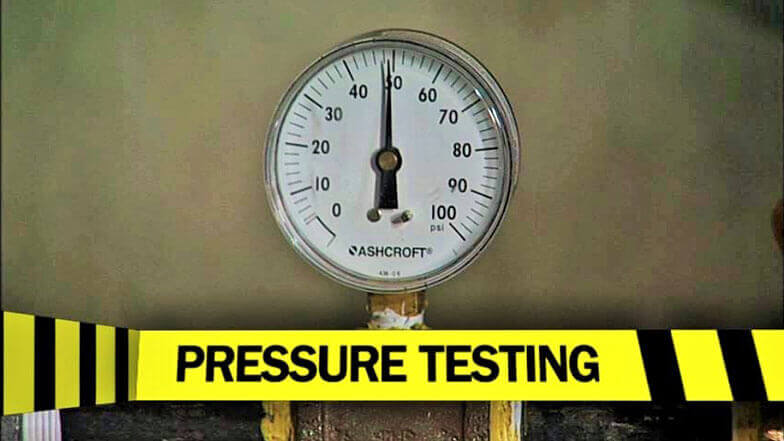

In a high-performance building, system integration is key. A balance between productivity, safety, good health, and energy efficiency is imperative. Failure to maintain one component may prevent the entire system from performing optimally.

With an emphasis on system v. equipment, these high-performance buildings differ from most other commercial buildings, where the focus tends to land more on a ‘break/fix’ mentality and focus only on basic wear and tear maintenance. With the equipment running independently of each other maintaining one part will not impact another.

Since high-performance buildings are normally ‘owner-occupied’ facilities, according to Starr, he believes that building and maintaining trust between the building owner and HVAC service provider is key to developing best practices and creating a successful strategic plan. Each building is unique and requires a different maintenance program to operate at its highest potential.

Read the full article from theNews and learn more on how to create a maintenance program that will result in higher performing systems, please click here.

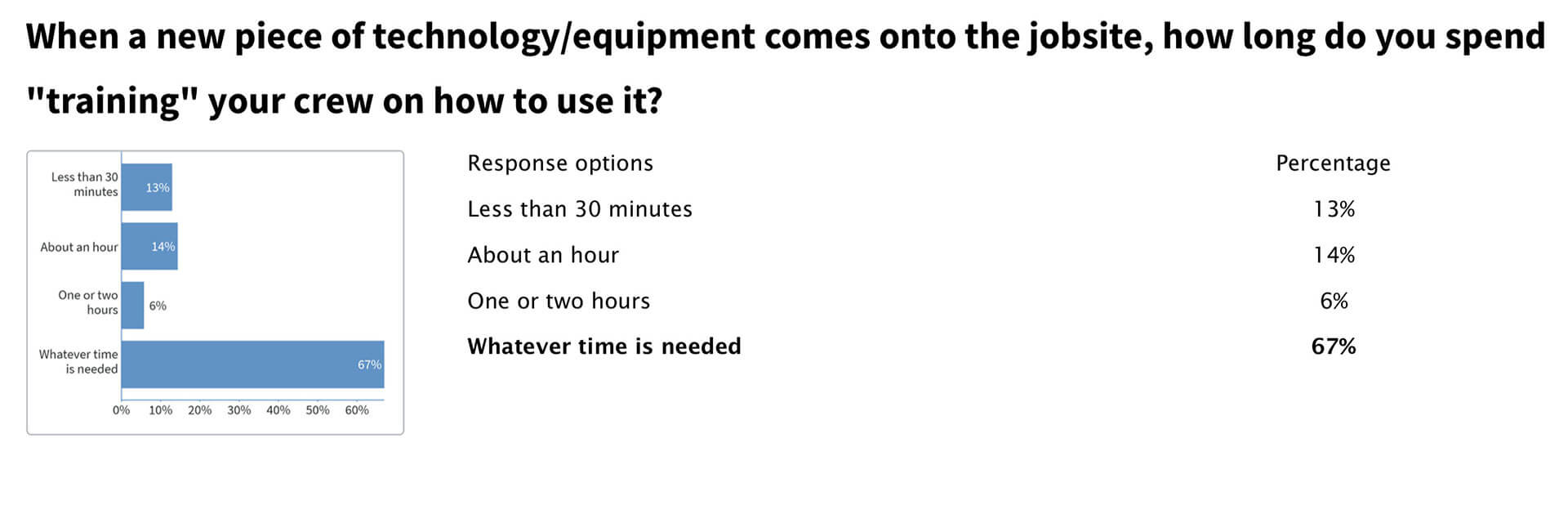

A balance must always be made in technology training. You don’t want to spend so much time on the training process that it keeps people from doing their jobs. You also want to make sure that people understand how to use it and follow up with added training if required. The good news from these results is that it seems like most field users are getting the right amount of time, regardless of the duration, and very few respondents appear to be getting new technology handed to them with little time to practice with it.

A balance must always be made in technology training. You don’t want to spend so much time on the training process that it keeps people from doing their jobs. You also want to make sure that people understand how to use it and follow up with added training if required. The good news from these results is that it seems like most field users are getting the right amount of time, regardless of the duration, and very few respondents appear to be getting new technology handed to them with little time to practice with it.