See DEWALT’s Recent Newsletter with a LinkedIn Live Event on September 16

Please see the most-recent DEWALT Newsletter with a LinkedIn Live event scheduled for this Wednesday, September 16 in support of SAFETY WEEK.

Please see the most-recent DEWALT Newsletter with a LinkedIn Live event scheduled for this Wednesday, September 16 in support of SAFETY WEEK.

MILWAUKEE TOOL’s product lineup has long been J.F. Ahern Co.’s choice of power tools because the same batteries could be used for a broad range of tools, saving time and money. Recently, Ahern had the opportunity to test out some of MILWAUKEE TOOL’s new MX FUEL™ Equipment System, including the first-ever cordless core drill, on a project that required drilling more than 1,500 holes through various types of walls, including block and concrete. Ahern found that the handheld core drill was much more efficient than a traditional drill, providing more control and more power. MILWAUKEE TOOL is an MCAA benefactor sponsor.

Visit the Smart Solutions Case Studies area of our website! You’ll see how other mechanical contractors found their win-win with productivity-enhancing and cost-saving applications from members of MCAA’s Manufacturer/Supplier Council.

Plus, you’ll find tips and ideas on other ways you and your company can save money and enhance your productivity.

Your sales teams are going through a major transition. Sales, as they have understood and embraced it throughout their careers, will never be the same again. The pandemic has shaken the very foundation of the sales process and how sales teams operate daily. How can you ensure that your sales team will be effective and successful in this new world? How can you help them navigate uncertainty and change and develop a performance mindset?

We invite you and your sales team to join us for a high-impact, interactive experience guaranteed to boost the performance of your sales personnel during this COVID and post-COVID era. This virtual program will take place on Wednesday, October 21st, 11:00 am – 12:30 pm Eastern time. Facilitated by internationally renowned expert, author and futurist Seth Mattison, this program will help you gain a better understanding of the key shifts happening in the realm of sales and its impact on the future of your business. After this program, your team will be better equipped to deal with this new reality and understand what it takes to be a high performer.

Topics to include:

The cost for this program is $500 per company which allows you to invite an unlimited number of your sales personnel to participate. We encourage you to invite your entire sales team to take part in this program together as various exercises and group discussions will be encouraged. However, if that is not possible, individual attendees will benefit greatly.

Seth Mattison is an Internationally renowned expert and author on workforce trends, generational dynamics, and business strategy. As Co-Founder and Chief Movement Officer of Luminate Labs, Seth advises many of the world’s leading brand and organizations on the key shifts happening around talent management, change and innovation, leadership, and the future of work.

His ideas have been featured in such publications as The Wall St. Journal, Forbes, The Huffington Post, and The Globe and Mail and was recently named to the Editors’ Picks for Speakers to Watch in 2017.

For the past decade Seth has shared his insights with thousands of business leaders around the world and has received accolades from many of the world’s best brands including: MasterCard, Johnson and Johnson, Microsoft, Kraft Foods, AT&T, PepsiCo, GE Energy, Cisco, State Farm, Merrill Lynch, Dow, and Disney. Seth was a very popular speaker at a recent MSCA conference.

Viega LLC has named Markus Brettschneider as its new CEO and President. He replaces Dave Garlow, who resigned effective September 1 after 20 years with the company. “I was attracted to Viega because of the culture, the customers, the portfolio and the great opportunities to grow,” he said. “When the opportunity came up, it was really quite a simple decision. I like working for a family-owned company with strong values and great culture, and I’m excited to continue this growth journey with the team.”

“Mr. Brettschneider is a growth-driven leader with many years of extensive professional and management experience in the international and American markets. He grew up in Germany, but spent almost his entire professional life outside of his home country – including more than eight years in the United States,” said Claus Holst-Gydesen, CEO of Viega Holding GmbH & Co.

Markus was hired after an international search. He most recently was with ABB, where he was Group Senior Vice President and Global Head of Marketing and Sales for Industrial Automation and Global Head of Group Solutions & Channels. ABB is a global technology company specializing in robotics, motion, electrification and automation technology.

Before that, he held management positions with FrieslandCampina, Refresco, SIG Combibloc and other firms. He has an MBA from Edinburgh Management School and a degree in international marketing from Cooperate State University in Schwenningen, Germany.

Dave Garlow, the outgoing CEO, resigned effective September 1. He was with Viega for 20 years in various roles. Under his leadership, Viega grew significantly in the North American market by accelerating the adoption of pressing technology. He will help ensure a smooth transition to Markus’s leadership. Dave said the thing he will miss most is the people and friendships in the industry.

“My decision to leave Viega now is made easier knowing that I’m leaving it in excellent hands. Markus has the skills and drive to ensure Viega’s continued growth and success,” Dave said.

Arc flash can change a service tech’s life in the blink of an eye. Fred Bothwell, CHST, safety coordinator at Speer Mechanical, an MCAA member, uses personal experience to impress upon Speer techs the seriousness of arc flash situations.

“While working as warehouse manager for one of the nation’s largest tire companies back in the early 1990s, I had requested getting the roof-top unit checked out by our A/C company. As the A/C guy was checking voltage, he lets out a yell. Then he gathers himself, starts doing the same thing and lets out another yell. It turns out that through perfect timing, at the same moment he touched the two leads to the unit, his beeper–on vibrate in his shirt pocket–was signaling him. He thought he was getting shocked. Later that year, when this same A/C guy was checking an industrial battery charger, he did get shocked for real. We had to call the emergency squad. He was okay, but it was a real ‘shock’ for all.”

Speer Mechanical has a Construction division, a Special Projects group, and a Service department. The company does everything from demolition to installing units inside mechanical rooms and on rooftops.

For roof-top installations, Speer Mechanical uses Rough Terrain forklifts, cranes, and helicopters to place the units on the roofs. The company’s Construction workers set the units in place and connect them to the building, and Service Techs connect the units to the power and provide ongoing service as needed.

The company began holding NFPA 70E classes, purchasing Arc Flash suits, and preparing workers to follow the rules in 2006. They were one of the first companies in the Central Ohio area to do so, which comes as no surprise since Speer has one of the area’s largest service departments.

Fred shares, “The Arc Flash suits were really stiff, bulky, and had the ‘beekeeper’ hood. You can bet everyone couldn’t wait to wear that outfit in our 90-degree humid Ohio weather.” He adds, “We held about five Arc Flash classes to cover the entire Service department.”

Later that year, Fred had the opportunity to present Speer’s NFPA 70E program to the UA local 189 union hall in Columbus, Ohio, where the company’s Service Techs are members. He said, “It was a fairly new topic in the area, and I think some of the information was surprising to those who attended. I reviewed cost, time spent, and what would be required in the future. Some of those things have since changed somewhat, but the importance of the training has not.”

“Training, following, and observing some 70+ Service Techs is my challenge,” Fred said. He noted that the company’s service technicians work on equipment pushing 480 volts or less. “Our work opportunities can occur at any time, at any jobsite, and on most any type of equipment,” he said. He added that “[A]ll Service Technicians are trained and tested to prove they know what they’re doing. They take classes at the union hall and attend training sessions held at Speer.” Fred noted that some vendor companies want Speer workers to have specific knowledge of certain equipment, which can have inner workings that change over time. He is pleased with their performance, saying, “Our Service Techs do a good job of working safely on all equipment and following the rules to continue being safe.”

MCAA offers resources to help member companies keep their workers safe when performing electrical work that falls within the purview of NFPA 70E.

In February 2020, we received new Arc Flash suits purchased from Enespro and the difference is astounding: no more stiff, uncomfortable outfits, but more like putting on regular clothing. As we continue to utilize the updates we all get from NFPA, the training we get from vendors and other outside sources, and the experiences we encounter on the job, we give ourselves the guidance and education necessary to be safe and successful.

Fred sums up the experience, saying, “The times may change, but the need for safety is a constant element. Not just safety first, but safety always.”

As the coronavirus pandemic flared up around the country, the U.S. Army Corps of Engineers rapidly built alternative care facilities to alleviate strain on local hospitals—and MCAA member contractors and manufacturer/supplier partners were there to help. In Chicago, Ferguson, Bradford White, Laars, and Sloan all provided needed materials in record time, and Helm Group (formerly Mechanical, Inc.) was among those working on the ground nonstop as the HVAC and plumbing contractor for the job. Ferguson; LAARS, a Bradford White Company; and SLOAN are all benefactor sponsors.

Visit the Smart Solutions Case Studies area of our website! You’ll see how other mechanical contractors found their win-win with productivity-enhancing and cost-saving applications from members of MCAA’s Manufacturer/Supplier Council.

Plus, you’ll find tips and ideas on other ways you and your company can save money and enhance your productivity.

MCAA’s Virtual Trade Show connects our contractor members with the members of MCAA’s Manufacturer/Supplier Council.

Participating companies highlight and link to new products, product lines, services, solutions or web pages of particular interest. Here are just a few of the recent additions:

Viega

Pressed for time? No Sweat. ProPress copper fittings make secure, flameless connections in 7 seconds or less. Approved for more applications than any other copper press fitting system, it’s what the pros use.

MSUITE

Track. Manage. Share. FabPro is the fabrication industry’s first cloud-based software created by mechanical contractors and proven to meet the needs of the fast-paced, ever-changing construction environment.

Find many more smart solutions in MCAA’s Virtual Trade Show!

Visit the Smart Solutions Case Studies area of our website to learn how other mechanical contractors found their win-win with cost-saving and productivity-enhancing applications from members of MCAA’s Manufacturer/Supplier Council.

This section of our website also includes tips and ideas to help your company save money and enhance your productivity. Don’t miss it!

Please join us in saying thank you to the MCAA members who have given to the John R. Gentille Foundation (JRGF) in 2020. Their support enables the JRGF to identify and work to solve the issues that confront the organized mechanical construction and service industry, challenges such as future workforce, productivity and technology.

Your peers supporting these vital efforts in 2020 are:

Learn more and donate on the JRGF website.

By: Jim Paretti, Michael J. Lotito, and William Hays Weissman

August 31, 2020

On August 28, 2020, the U.S. Department of the Treasury issued guidance for employers with respect to the deferral of the employee portion of certain payroll taxes. This guidance stems from a presidential memorandum issued earlier in the month authorizing employers to defer payment of these taxes. That memorandum allowed for the deferral of the employee portion of federal payroll taxes (6.2% for Social Security and 1.45% for Medicare) from September 1, 2020 until December 31, 2020. The memorandum allows employers to defer payment of the employee portion of these payroll taxes for workers earning less than $4,000 on a biweekly basis (roughly $104,000 annually).

Treasury’s guidance makes clear that an employer may elect to defer the payment of the employee portion of these taxes on “applicable wages” until next year, when they would be owed in installments between January 1, 2021 and April 30, 2021. “Applicable wages” are defined as those wages paid to an employee on pay dates between September 1, 2020 and December 31, 2020, “but only if the amount of such wages or compensation paid for a bi-weekly pay period is less than the threshold amount of $4,000 or the equivalent threshold amount with respect to other pay periods.” The guidance specifies that applicable wages are determined on a pay period by pay period basis. Finally, the guidance makes clear that employers are required to pay these taxes to the federal government, but goes on to state that employers “may make arrangements to otherwise collect the [due taxes] from the employee.”

The guidance leaves several clear takeaways. First, it is clear that an employer is permitted to defer payment of these taxes, but is not required to. Second, it is likewise clear that unless further action is taken (likely by Congress), these taxes are merely deferred, not forgiven, and will be due by the end of April 2021. Finally, it is not clear what, if any, role an individual employee plays with respect to determining whether they want their share of these taxes deferred, or paid in the normal course. Employers will want to keep each of these points in mind as they evaluate whether or not to participate in this elective deferral.

It is unclear whether Treasury will issue additional guidance regarding this program. Littler WPI will keep you apprised of relevant developments.

We recognize that virtual events simply cannot replace our in-person educational conferences and networking opportunities, so MCAA has combined several approaches and techniques to create the PCA Virtual Education Series hosted by JPG Plumbing & Mechanical Service, Inc. This year, MCAA attendees will be able to virtually walk through JPG Plumbing & Mechanical Service’s operations through seven workstations as representatives speak about the various aspects.

Once a week, for seven weeks, JPG Plumbing & Mechanical Service will highlight one of the seven workstations through a 15-minute video, followed by a 45-minute discussion of operational costs and Q&A between attendees around the country with similar operations in their companies.

The first module highlights the commercial plumbing service vehicle itself. In the video, JPG Plumbing & Mechanical Service covers the type of vehicle, the equipment and tools on each vehicle and why/how they wrap it with advertising. Each attendee will receive a comprehensive list of the tools mentioned, as well as a link to the manufacturer website and an MSRP. The video will be followed with an open discussion between attendees on how they spec a vehicle or vehicle type differently and what tools they use. By the end of the module, attendees will have a much more thorough understanding of the cost to put a plumbing service truck on the road.

Although it is hard to match the insight and knowledge that attendees receive from connecting with peers and networking, MCAA believes this approach is certain to provide greater detail and information for our members, as if one were in the JPG Plumbing & Mechanical Service facility themselves. You can still register – don’t miss out!

On August 31, 2020, OSHA published a final rule revising the beryllium standard for the construction industry. Although it is exceedingly rare for the agency’s beryllium standard to affect mechanical construction employers, if there are operations on any of your jobsites where your workers could be exposed to airborne concentrations of beryllium, you will be required to comply with the standard. For example, if your workers are hanging pipe in an area on a jobsite where abrasive blasting is being performed, it’s conceivable that your workers could be exposed to beryllium, and you would be required to make inquiries, and establish protective measures.

The primary protective measures include:

The original standard took effect on May 20, 2017, but since then, OSHA has only enforced the permissible exposure limit (PEL). However, OSHA will begin enforcing the remaining provisions of the standard, including the revised provisions, which were published in the federal register on August 31, 2020, starting September 30, 2020.

If you have any questions about the standard, please contact Pete Chaney at pchaney@mcaa.org, or 301-990-2214.

MCAA believes that ergonomics should be a standard part of every company’s overall safety program. Recently MCAA partnered with The Center for Construction Research and Training (CPWR), Washington University in St. Louis, and Best Built Plans to develop and record a webinar on Creating a Contractor Ergonomics Program to Reduce Soft Tissue Injuries Among Construction Workers. The webinar is ideal for helping viewers understand the vital components of a successful ergonomics program, and why the components are so vital.

With the recent increase in violence in America, now is a good time to revisit MCAA’s award winning video on workplace violence prevention and protection. The principles of situational awareness presented in the video apply absolutely everywhere, regardless of whether you’re in the workplace or elsewhere.

The PCA announced the opening of a new Virtual Education Series today that goes beyond the typical Zoom meeting that we have become accustomed to. The seven-episode series features an in-depth look at JPG Plumbing & Mechanical Services, a member contractor based in Jessup, MD. Each episode is a mini case study in a different area of operations and hosted by the JPG employees in charge of the relevant work.

What makes this series different than a typical webinar is that each area of focus includes a 15-minute video to showcase the operation, a workbook that includes products, materials and costs as well as an interactive interview with the host to get more insight into functions and share attendee solutions.

“We were all set to do a similar conference on plumbing service in person,” JPG President and CEO John Geiling stated. “When COVID hit, instead of cancelling it or doing it via a PowerPoint presentation, we decided to try to figure out how to expand out the content and share even more information. The result is that instead of a 15 minute demo that we would have done in our shop, we can get into a lot more details, share more information and get insight from other members as to how their operations are different.”

Beginning on Wednesday, September 23 the series will host a live module each week until its conclusion on November 4. Each Wednesday, the session materials will be posted with a link to the live episode posted upon its completion. Materials will be available throughout the duration of the series. The schedule includes:

Registration for the series is $400 and open to PCA, MCAA and MSCA members only.

To learn more, visit the PCA Virtual Education Series Site.

Support for the series is brought to you by MCAA’s Sponsoring Benefactors.

Honeywell has issued an Immediate Stop USE Notice for certain models of Miller MightEvac and MightyLite self-retracting lifelines (SRLs) manufactured within a specific time frame. The notice only affects specifically listed models, with identified manufacturing dates or re-certification dates between October 27, 2016 and October 6, 2018. Models outside of this date range, including new units, are not affected by this notice. If your company uses these SRLs check Table 1 in the attached notice to determine whether your SRLs are affected. If so, they should be removed from service immediately. Honeywell is making arrangements for their return and replacement. That information is forthcoming.

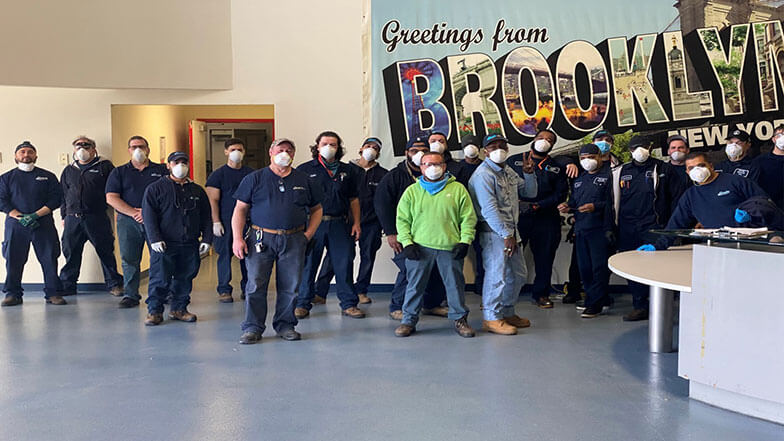

During the height of the COVID-19 crisis in New York City in April, MCAA member Donnelly Mechanical was an integral part of converting two facilities within Queens and Brooklyn into temporary field hospitals. These hospitals were staffed with doctors and nurses from around the country who traveled to New York to help treat COVID-19 patients and to relieve the burden from the nearby, overtaxed hospitals.

Following a fast-paced, intense, competitive vetting process, Donnelly Mechanical was contracted by SLS Construction to install oxygen lines at the Billie Jean King National Tennis Center in Queens. Based in Galveston, Texas, SLS Construction provides general contracting and construction management services with a specialty in aiding disaster relief efforts. Within just a few days, the combined effort between SLS and Donnelly converted a dozen indoor tennis courts into a temporary overflow hospital with 450 additional beds.

Once the hospital was up and running, Donnelly returned to the site to assist with additional work. Fully functional ventilators require high-pressure oxygen that meets precise specifications. Donnelly’s service team ran high pressure oxygen tubes to the ventilator location in Ward 1, where many COVID-19 patients were being treated. The team took every possible safety precaution, including the use of proper personal protective equipment (PPE) and HAZMAT suits.

The GC was thoroughly impressed by Donnelly’s work and quickly awarded them a similar conversion project at the Brooklyn Cruise Terminal. Work to install oxygen lines at the 750-bed facility started immediately.

Teams of 25-30 men worked very long shifts to successfully complete the conversion in five days.

The dedication of an incredible group of service technicians and field supervisors from Donnelly’s HVAC Service Team played a crucial role in the emergency response to the COVID-19 pandemic in New York City.

The team members involved in those projects were:

MCAA thanks the Donnelly team and all of our members who have worked tirelessly to protect their communities’ safety. We’re all in this together.

MCAA’s Virtual Trade Show connects our contractor members with the members of MCAA’s Manufacturer/Supplier Council.

Participating companies highlight and link to new products, product lines, services, solutions or web pages of particular interest. Here are just a few of the recent additions:

Watts Water Technologies

Get the job done Pronto!™ Now available in Cast Iron as well as PVC, this dual adjustable floor drain from Watts® provides maximum efficiency and accuracy during installation. Designed for post-pour adjustment with flexibility in mind, Pronto! key product features save contractors time and labor costs.

DEWALT Industrial Tool Company

DEWALT®, the leading manufacturer of power tools, hand tools, accessories and storage solutions, announces that its new ToughSystem® 2.0 Storage System, which offers improved durability and modularity versus previous units, is now available.

Find many more smart solutions in MCAA’s Virtual Trade Show!

Visit the Smart Solutions Case Studies area of our website to learn how other mechanical contractors found their win-win with cost-saving and productivity-enhancing applications from members of MCAA’s Manufacturer/Supplier Council.

This section of our website also includes tips and ideas to help your company save money and enhance your productivity. Don’t miss it!

MCAA’s GreatFutures Virtual Fall Program has kicked off! Each of the 17 presentations is meant to help students navigate the proposal and bid process for the annual MCAA Student Chapter Competition project.

Did we mention registration is free and you only have to register once for ALL of the presentations!

Once registered, you will receive a confirmation email with the MCAA’s GreatFutures Virtual Fall Program website login instructions. This website includes:

We encourage you to attend as many presentations live to interact with fellow students and engage with the presenters in the presentation Q&A. If you are unable to attend any of the sessions live, don’t you worry, the recorded presentations will be posted on MCAA’s GreatFutures Virtual Fall Program website AFTER the live session.

MCAA is sending a weekly Monday reminder email to registered attendees, highlighting the presentations for that week. Don’t forget to add them to your calendar!

MCAA’s GreatFutures Virtual Fall Program is sponsored by

This updated program is now available virtually!

This interactive, three week virtual program will be held every Tuesday and Thursday at 2 PM EDT, starting November 3 – 19, 2020. Sales Basecamp is where it begins for entry-level service sales personnel in the HVACR and plumbing industry. This program will prepare this recent hire or employee new to a sales position with all the relevant skills necessary to confidently sell HVACR and plumbing services while creating added value for the customer. The skills and knowledge attained in this class will become the strong foundation on which you build a long and successful career in service sales.

Class size is limited, so make sure to sign-up today!