During the negotiation process of the Tax Cuts and Jobs Act at the end of 2017, the tax credit for R&D spending was temporarily removed. Fortunately, MCAA and others worked hard to ensure that the final bill re-inserted the language for the Research Tax Credit (“RTC”) and made changes that potentially increase the credit by more than 20%. With the RTC in place, contractors are able to continue to claim tax credits for qualifying BIM and design work. Unfortunately, many mechanical and plumbing contractors are unaware that they can even claim part of their design and bid work for these tax credits.

This article is intended to offer an overview of the Research Tax Credit for mechanical contracting personnel presented in general non-tax terms, wherever possible. The credit is, however, “tax based”, and as such, the inclusion of all of the applicable rules for every situation is not possible in a brief discussion.

In order to qualify for the research tax credit, activities must pass several tests. Although these tests are fairly specific, “qualifying activities” are generally much broader than many people think. When contractors hear the term “research” they often associate the term with scientists wearing white lab coats who are mixing chemicals in beakers. However, the Internal Revenue Code definition of research, as defined under IRC §41, is much broader than this traditional definition. As a result, many contractors may typically associate a large portion of their research activities as “routine” or “ordinary”, when in fact many of these activities might qualify for the Research Tax Credit.

To successfully build a structure, there may be experimentation or an iterative process on technical design issues and the installation process to properly build it. Although it might seem complicated if you are not claiming these credits, many contractors have been doing so for years. Before you begin, it is recommended that MCAA members contact their tax professionals to ensure that they are properly claiming the appropriate costs and activities under the RTC.

To begin, the Internal Revenue Code states that the activities “must be intended to discover information to eliminate technical uncertainty concerning the capability or method for developing or improving a product or process, or the appropriateness of the product design”. The Code also requires a “process of experimentation” involving the evaluation of alternatives, confirmation of hypotheses through trial and error, testing and/or modeling (this can include iterative steps in evaluating design alternatives, alpha/beta tests, pilot trials, scale-up testing, marketing/field tests directly associated with the R&D efforts, qualification Trials, etc.). Finally, wages, supplies, and contracts associated with qualifying activities qualify. The expenditures can also be either capital or expensed items.

Broadly, this includes any activity where there is some technical uncertainty involved in the development or improvement efforts- i.e., is there a technical problem that needs to be solved before you can effectively launch/implement this equipment design, software, product, process, prototype, etc.? Personnel who are directly engaged in resolving the technical issues will qualify and those individuals who have a support role will also qualify (i.e., performing alpha/beta/unit testing, collecting data or writing programs to collect data, supervision, technical project management, etc.)

Uncertainty exists if the information available to the contractor does not establish the capability or method for developing or improving the product/process or the appropriate design of the product/process. The required level of uncertainty may be established in instances where your work requires the resolution of technical issues when either designing the mechanical and plumbing system or working from a set of drawings that are incomplete or need modification to function.

The definition of activities that qualify for the credit is fairly broad and the driver for the effort can be to produce a new, better or more competitive product/process, to increase reliability/quality, to increase general product/process safety, to respond to new federal/state requirements, to reduce costs or increase speed/efficiency, etc. Furthermore, the success or the degree of technological advancement is not a factor.

Below is a representative sample of activities a taxpayer would typically perform, which often times are misclassified as “routine” or “non R&D” related:

- Evolutionary advancements to the functionality, performance, reliability or quality of an existing product (Change orders for process improvement);

- Development of prototypes or models to prove out conceptual ideas (Including BIM);

- Experimentation to verify if an existing construction technique or process can support a new product with differing characteristics (Testing point loads);

- Experimentation to verify if a new or existing construction technique or process can be implemented in a new or different geographic region, new environment, or different industry/application;

- The design and development of custom equipment, tooling, molds and/or dies;

- The development of microcode used within machinery or robotics;

- The redesign of an existing construction or building process to improve efficiencies, increase safety or reduce operating expense;

- Testing to prove out the use of new materials in existing products;

- Plant and/or Process scale-up activities;

- Qualifying “Bid and Proposal” efforts; and

- The development of custom software that is either intended to be used internally or sold, leased or licensed to third parties as a commercial product offering.

However, simply because some items may be new, unique, customized or involve special problems does not mean that they will automatically qualify for a credit. For instance, there may be options or choices in regard the application of standard engineering techniques, but no uncertainty in regard to the resolution of a technical issue facing the project team. Qualifying activities that are intended to resolve technical uncertainties should also involve some iterative type of testing, experimentation, the consideration of alternatives, trial and error evaluations, prototyping, validation, etc.

Thus, although no qualifying activity might occur for most HVAC systems (even where custom designs are involved), technical uncertainty might arise on mechanical engineering and/or design efforts in instances where there are unusual requirements involving, for example: complex temperature, humidity, pressure, ambient air ratio range controls with differing protocols for numerous chambers/rooms; the need to design for particulate and/or chemical fume control/mitigation where the chemistry might require special construction materials; unusual space limitations, local regulations, cost mandates, etc.; instances where numerous alternative methodologies for technical solutions are necessary; development of technical alternatives to address repeated system failures; etc.

The PATH Act of 2015 made the Research Tax Credit permanent but also broadened the impact of the credit for many small to mid-sized businesses. Starting January 1, 2016, small businesses that meet certain criteria can also use the Research Tax Credit to offset the FICA employer portion of payroll tax, with a credit cap of $250,000 for each eligible year.

– – –

Mike Foley is the Managing Partner at Foley & Smith, LLC, a firm specializes in Research Tax Credits.

Mike D’Allesandro is the Managing Director at Research Tax Credits, LLC

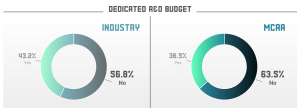

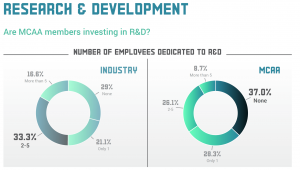

Most respondents that identified as MCAA members reported that they had one or two people dedicated to R&D, while 37% do not have employees dedicated to R&D. During a presentation on the topic at MCAA19, MCAA’s Director, Construction Technology Sean McGuire explained, “While we are seeing more members take technology seriously, smaller companies are going to always be more limited on budget and manpower that they can dedicate towards research and implementation. Larger GCs and CMs can absorb these costs a little easier simply as a function of their size.”

Most respondents that identified as MCAA members reported that they had one or two people dedicated to R&D, while 37% do not have employees dedicated to R&D. During a presentation on the topic at MCAA19, MCAA’s Director, Construction Technology Sean McGuire explained, “While we are seeing more members take technology seriously, smaller companies are going to always be more limited on budget and manpower that they can dedicate towards research and implementation. Larger GCs and CMs can absorb these costs a little easier simply as a function of their size.”