Category: Safety

SDS BinderWorks

SDS BinderWorks, MCAA’s preferred safety data sheet service, helps reduce costs and time associated with SDS-related efforts, and it keeps the compliance process simple and convenient. It offers GHS-compliant SDSs online with flexible delivery options in digital and hardcopy formats. To establish service or learn more, contact SDS BinderWorks, Inc. at 877-433-7774 or via email. MCAA and MSCA members save 5 percent on any subscription plan.

Model Excavation Safety Program

This model guides you through establishing a program that minimizes risk to your employees and ensures your compliance with OSHA requirements. It makes development and implementation of such a program as easy and cost-effective as possible.

Model Safety and Loss Prevention Program for Construction

This basic model safety program is fully customizable to suit your mechanical construction company’s individual needs. A variety of topic-specific model programs are available to supplement this basic program.

Toolbox Safety Talks for Fabrication Shops

This publication presents 52 safety talks that are specific to pipe fabrication shops. Topics covered include: general fabrication shop safety, personal protection, respiratory hazards, material handling, welding/cutting/brazing, fire prevention and protection, power tools and specialized equipment used in fabrication shops.

Toolbox Safety Talks for Construction Contractors – Volume V

This fifth volume of short duration safety training toolbox talks will further expand your safety training library. These talks will help you remind your mechanical construction workers to identify jobsite safety and health hazards and protect themselves from those hazards.

Distracted Driving Reduction and Prevention Guide

Learn about the growing issues surrounding occupational distracted driving. This guide provides information about the hazards, liability, regulatory initiatives, and company policies associated with distracted driving.

Rigging Safety Guide

This user-friendly guide will assist mechanical industry workers in planning for safe rigging operations involving mechanical industry equipment and materials. Information on key safe rigging practices is provided to help workers prevent rigging/lifting-related

injuries; prevent damage to equipment, materials and property; and perform their rigging responsibilities more efficiently.

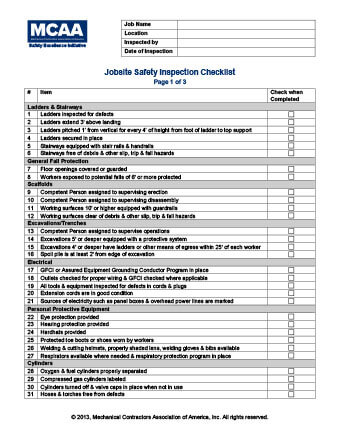

Jobsite Safety Inspection Checklist

This checklist can be easily customized to help keep you organized and on track when you perform safety inspections.

Model Respiratory Protection Program

Ensure that your company complies with OSHA respiratory rules and protect workers from exposure to airborne hazards.

Model Lockout/Tagout Program

Protect your workers from hazards associated with energy sources. This program explains what lockout/tagout procedures mean, why they’re important and what steps must be taken to comply with OSHA’s lockout/tagout standard.

Model Mold Prevention Program

Learn how to establish company procedures to help reduce the risk of litigation, which can occur due to the growth of mold on jobsites.

Model Hazard Communication Program

OSHA’s Hazard Communication Standard requires employers to explain to their employees what chemicals they may be exposed to in the workplace, the hazards associated with use of or exposure to these chemicals and the steps they can take to protect themselves. This model program can be easily customized to create a company-specific program that complies with the standard.