Growth Up 25% In One Year with ServiceTrade & Hurst Mechanical

Since adopting ServiceTrade, Hurst Mechanical experienced 25 percent growth in a single year, a testament to the efficiencies gained through the platform. In addition, using ServiceTrade to streamline preventive maintenance (PM) scheduling and management led the company to increase PM volume by 20 percent.

Hurst Mechanical is a leading provider of commercial and industrial HVAC services in West Michigan. They faced significant inefficiencies that were both time-consuming and prone to errors, including lengthy quote times, cumbersome purchase orders, and difficulties tracking their customers’ service history. Additionally, they lacked timely access to crucial business insights. After years of managing their business on paper and a failed attempt with another software solution, in 2020 they ultimately selected ServiceTrade for its comprehensive features and user-friendly interface.

From Skeptics to Wizards

After switching to ServiceTrade, Hurst Mechanical quickly saw the benefits. In two months, the team was up and running on the software. Despite some initial reluctance, particularly from veteran technicians who had experienced previous software failures, the transition proved to be highly successful.

Those once-skeptical technicians have since become proficient users of ServiceTrade. Alex Haan, vice president of service at Hurst Mechanical, now describes them as “wizards” with the software. Their ability to quickly adapt and fully use ServiceTrade’s features has been a key factor in the company’s enhanced efficiency and operational success.

Streamlining Pays Off

Using ServiceTrade revolutionized Hurst Mechanical’s operations. The platform has streamlined processes, particularly in quoting and parts management. “It used to take three days to deliver a quote to a customer—but now it takes less than one,” said Haan.

Technicians use the service history feature to access previous job details to understand prior customer interactions, reducing time spent on phone calls with the office. ServiceTrade made obtaining purchase orders significantly easier, eliminating unnecessary delays. Now, technicians can issue purchase orders and enter receipts directly in the mobile app and plan ahead for parts without wasting time calling the office.

Take advantage of this free one-hour webinar from ServiceTrade, Slash Tech Downtime.

Haan noted that ServiceTrade has enabled the company to streamline operations across the board, creating a more efficient workflow that supports sustained growth. A significant part of the

success is the growth in PM, with PM agreements now making up roughly 40 percent of Hurst Mechanical’s business. ServiceTrade not only streamlined scheduling and management of PM but also helped Hurst Mechanical uncover more high-profit repair opportunities, contributing to the overall revenue increase.

Haan highlighted that the new processes allow them to keep up with the growing demand for PM services, ensuring that Hurst Mechanical can provide timely and high-quality maintenance to their clients. The proactive approach to maintenance has also strengthened customer relationships, positioning Hurst Mechanical as a reliable partner in their clients’ operational success.

Read Service Trade’s blog, Eight Ways to Sell Commercial HVAC Contracts in 2024.

Information Increases Efficiency

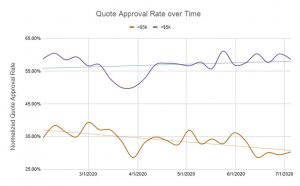

Previously limited to monthly reviews, Haan now uses ServiceTrade’s business reporting to review the backlog report daily, ensuring PM work is on track. The labor analysis report helps track job types and growth trends. This real-time data access empowers informed decision-making and sustained growth. Additionally, Hurst Mechanical can access revenue reports and other critical data anytime, allowing for continuous monitoring and optimization of business performance.

Hurst Mechanical’s strategic adoption of ServiceTrade has transformed their service delivery and operational efficiency. By leveraging ServiceTrade, they continue to drive growth and success, positioning the company as a preferred partner among their customers.

For more information, visit servicetrade.com.