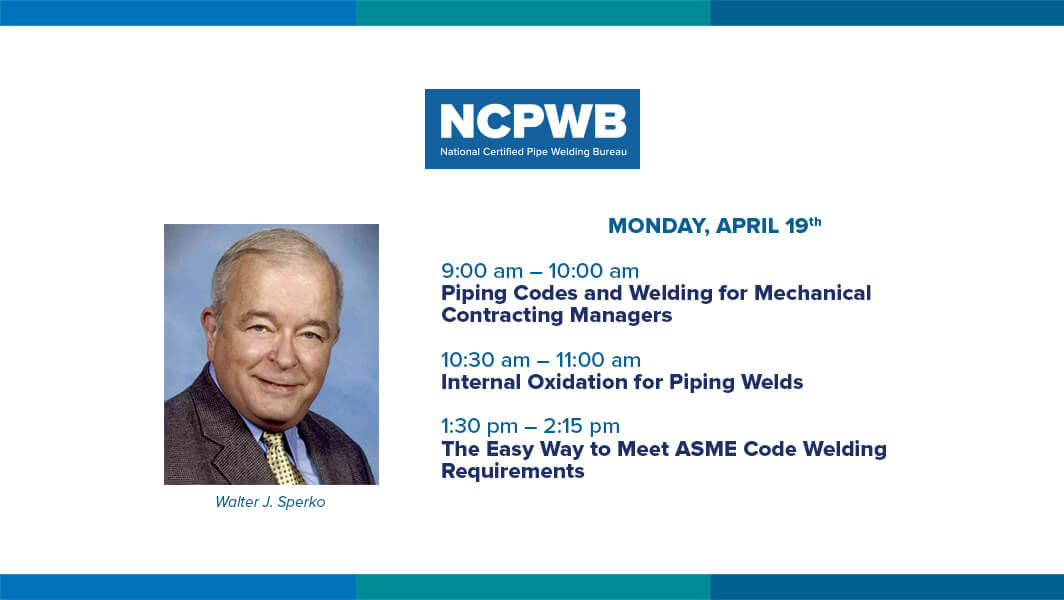

Piping Codes and Welding for Mechanical Contracting Managers

9:00 am – 10:00 am

There are key aspects about pipe welding that Project Managers and supervisors must understand in order to be sure that welds their company makes are suitable for service and meet contract and Code requirements. Despite the idea that codes are difficult to meet, when properly understood and followed, they can protect a contractor from unreasonable demands by owners and their engineers. Knowing what codes cover allows managers to identify unusual and costly requirements in customer specifications. Understanding what goes on in assembling and welding pipe joints illustrates the importance of performing inspections at critical steps. Codes impose radiography or ultrasonic examinations and customers frequently add additional requirements and knowing how to manage those requirements on a project can make or break a job.

Internal Oxidation for Piping Welds

10:30 am – 11:00 am

When welding stainless steel and nickel alloy piping using an open root or consumable insert, the root side of the joint (i.e., the inside surface of the pipe at a weld) must be protected from the oxygen in the atmosphere, otherwise the liquid weld metal will oxidize badly creating a surface that is not only discolored but is also quite rough. This roughness and discoloration will reduce the corrosion resistance of the metal at the weld. In this webinar you will learn what is acceptable level of discoloration of the root side of the stainless-steel pipe weld and provides general guidance on the level of root surface discoloration that can be tolerated for some service conditions

The Easy Way to Meet ASME Code Welding Requirements

1:30 pm – 2:15 pm

A contractor has liability when contracts specify meeting ASME B31 Codes. When it comes to welding procedures and welder qualification, meeting those requirements can be challenging. Those responsibilities can be met easily as members of the NCPWB by following a few simple rules that will be explained during this presentation.

About the Presenter

Walter J. Sperko is president of Sperko Engineering Services, Inc. in Greensboro, N.C. The firm provides engineering consulting services to customers in the metal fabrication industries in welding, metallurgy, manufacturing processes, piping and pressure vessel design, inspection and quality assurance. The firm also prepares and conducts training programs in ASME Section IX, piping, welding and metallurgy, as well as custom-tailored programs related to metal fabrication. Prior to his consulting business, Sperko was with RECO North Carolina, Inc. (Colfax, N.C.), ITT Grinnell Industrial Piping, Inc. (Kernersville, N.C.) and Ebasco Services, Inc. (New York, N.Y.).